Looking for a FMEA Template in Excel?

QI Macros has several ready-made FMEA templates for you!

Create FMEAs using QI Macros

- Open a FMEA template from QI Macros menu

- Just drop in your data.

- The template guides you through the process and calculates risk priority # for you.

What is Failure Modes and Effects Analysis?

Failure Mode and Effects Analysis (FMEA) is a methodology used to analyze and prevent potential failures before they happen. When you are designing a product or a process, especially one that can affect human life, you want to anticipate all of the ways things could go wrong. The automobile and airline industries do this routinely to mitigate and prevent potential problems.

A good FMEA Template can guide you through the process and help you document and organize your analysis.

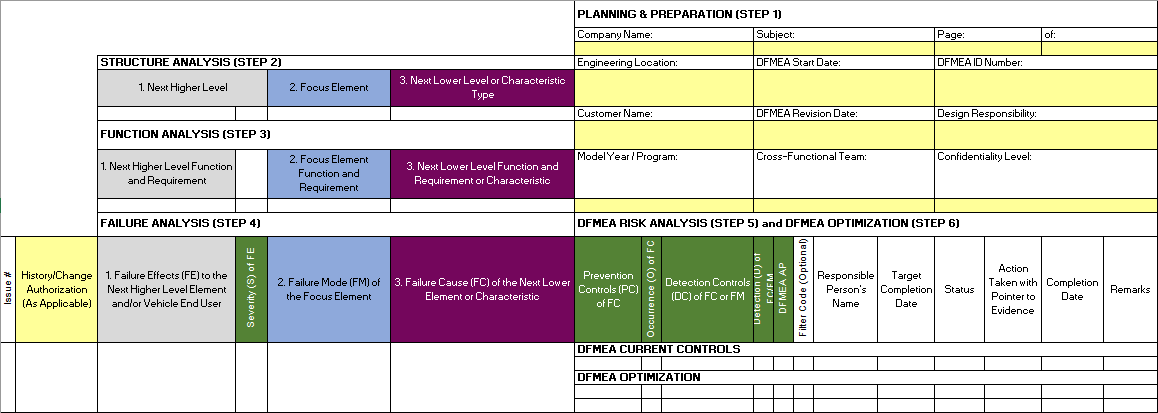

Example of the FMEA Template in QI Macros for Excel

The FMEA Template Guides You Through This Seven-Step Approach

The updated AIAG & VDA FMEA 1st Edition handbook describes a Seven-Step approach that guides design development and process, along with monitoring and FMEA system response:

- Planning and Preparation: Develop a FMEA project plan.

- Structure Analysis: Using a visual method, decide which product or process that will be analyzed.

- Function Analysis: For both your Design (DFMEA) and Process (PFMEA), choose which functions will be performed, along with HOW you will evaluate their performance(s).

- Failure Analysis: What is/are the failure mode(s)? And what effects or causes these failures?

- Risk Analysis: Assign severity of risk, along with occurrence and detection of the cause of failure (4th Edition). This allows you to estimate your level of design or your process risk.

Action Priority (AP): Assign a value (1-10) for each severity/occurrence/detection (5th Edition). AP will be automatically assigned as a High/Medium/Low Priority. - Optimization: Based upon your Risk Analysis from step 6, decide which aspects of your FMEA will require actions that reduce your risk. And what are those actions?

- Results and Documentation: Document your findings! How did you reduce risk, and what were the actions taken? Create a comprehensive report that shows your findings.

FMEA, DFMEA, PFMEA and FMEA-MSR

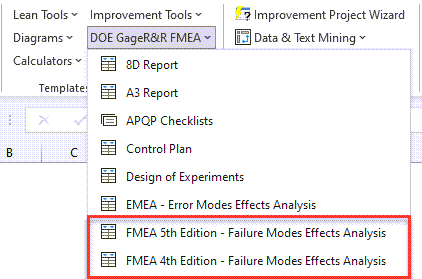

QI Macros FMEA Template is actually a series of 11 templates for all of the Process FMEA's (PFMEA), Design FMEA's (DFMEA) and FMEA for Monitoring and System Response (FMEA-MSR) defined in the AIAG FMEA 5th Edition (AIAG & VDA FMEA 1st Edition) and FMEA 4th Edition.

Both template editions can be found in QI Macros menu:

Complete List of the FMEA Templates in QI Macros for Excel

FMEA 5th Edition (AIAG & VDA FMEA 1st Edition) Templates |

DFMEA |

PFMEA |

FMEA-MSR |

|---|---|---|---|

| Form A: Standard DFMEA | X |

||

| Form B: Alternate DFMEA | X |

View A: DFMEA Software View | X |

| Form C: Standard PFMEA | X |

||

| Form D: Alternate PFMEA | X |

||

| Form E: Alternate PFMEA | X |

||

| Form F: Alternate PFMEA | X |

||

| Form G: Alternate PFMEA | X |

||

| View B: PFMEA Software View | X |

||

| Form H: Standard FMEA-MSR | X |

||

| View C: FMEA-MSR Software View | X |

FMEA 4th Edition - Description |

DFMEA |

PFMEA |

Machinery |

|---|---|---|---|

| Checklist | X |

X |

|

| Basic Form with minimal information (SAE J1739) | X |

X |

|

| Adds requirements column | X |

X |

|

| Form A with Prevention controls to left of Occurrence column | X |

X |

|

| Form B with Prevention controls to left of Occurrence column | X |

X |

|

| Form D with separate columns for cause/failure mode in Detection Design Controls | X |

X |

|

| Form B with separate columns for Responsibility, Target Completion Date, Actions Taken and Completion date | X |

X |

|

| Form B with ID, Product and Process w/in a bridged Requirements Column | X |

||

| Form D and G combined | X |

||

| Basic Form – Two columns for machinery and design controls | X |

||

| Basic Form – One columns for combined machinery and design control | X |

Learn More...

- FMEA Example with Step by Step Instructions

- Other Design for Six Sigma Tools in QI Macros

Haven't you waited long enough?

Start creating your FMEA Diagram in just minutes.

Download a free 30-day trial. Get the FMEA Diagram now!

The FMEA Diagram is one of many tools included in QI Macros add-in for Excel.

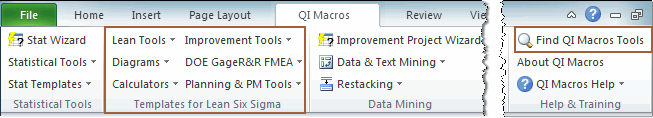

QI Macros adds a new tab to Excel's menu, making it easy to find any tool you need. If you can't locate a tool, use the find tools feature on the far right side of QI Macros menu.