Looking for an FMEA Example?

Step by Step Example of How to Complete an FMEA

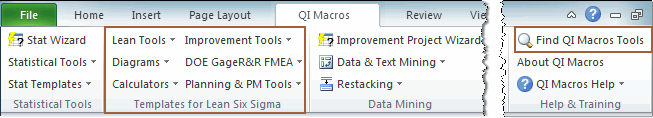

QI Macros FMEA Excel Template makes this process even easier.

FMEA Step |

FMEA Example |

| 1. Identify each Part or Process Step | Preparation for an MRI - magentic resonance imaging - in a hospital |

| 2. Identify Potential Failure Modes - All of the manners in which the part or process could fail. | Cracked, loosened, deformed, leaking, oxidized, overlooked, etc. For example, MRI's produce intense magnetic fields. One patient was killed by a flying fire extinguisher pulled off the wall by the MRI. |

| 3. Identify any Potential Effect(s) of Failure - Consequences on other systems, parts, or people. | Noise, unstable, inoperative, impaired, injury, death, etc. The consequence of a fire extinguisher getting pulled off of the wall is that it could hit someone. |

| 4. Rank Severity of the Effect (1-10) | 1 = none or no effect, 10 = "hazardous without warning" For example: a tire blow out may be rated a 2 while a a fire extinguisher to the skull would be rated a 10. |

| 5. Evaluate Potential Cause(s) / Mechanism(s) of Failure | List every potential cause and/or failure mechanism such as Incorrect material, improper maintenance, fatigue, wear, etc. |

| 6. Rank the Possibility of Occurrence (1-10) | 1 would be remote while a 10 would be high |

| 7. List Your Current Design Controls. | List prevention and detection activities to assure design adequacy and prevent or reduce occurrence. |

| 8. Rank Your Ability to Detect a Failure Using these Controls (1-10) | 1 is almost certain to 10 absolute uncertainty. |

|

9. Calculate the risk-priority number (RPN) for each part or step (4th Edition). Assign a value (1-10) for each severity/occurrence/detection (5th Edition). |

RPN = severity * occurrence * detection (4th Edition) AP (Action Priority) = severity * occurrence * detection (5th Edition) |

| 10. Design Recommended Improvement Action(s) | Design additional actions to reduce severity, occurrence and detection ratings. Severity of 9 or 10 requires special attention. |

| 11. Assign Responsibility & Target Completion Date for implementing designed improvements. | |

| 12. Monitor Actions Taken and effects on RPN. |

Check out aiag.org for a comprehensive FMEA Manual.

Haven't you waited long enough?

Start creating your FMEA Diagram in just minutes.

Download a free 30-day trial. Get the FMEA Diagram now!

The FMEA Diagram is one of many tools included in QI Macros add-in for Excel.

QI Macros adds a new tab to Excel's menu, making it easy to find any tool you need. If you can't locate a tool, use the find tools feature on the far right side of QI Macros menu.