Need to Calculate Process Capability Metrics?

QI Macros will calculate them for you!

You Don't Need to Learn Formulas - You Just Need the Right Software

QI Macros Histogram calculates several process capability analysis metrics for you so you don't need to learn any formulas. However, if you want to dive deeper, descriptions and formulas for these metrics are described below.

- Cp and Cpk Process Capability Metrics

- Pp and Ppk Process Performance Metrics

- Other Process Metrics

- Why did My Metrics Turn Red?

Other Process Capability Metrics

Capability Ratio - Cr Formula

The Capability Ratio indicates what proportion of tolerance is occupied by the data.

Cr = 1/Cp

Cp = 1.33 ~ Cr = 0.75 (data fits 75% of tolerance)

Cpm Formula

The Cpm is an uncommonly used Capability Index that can be used when you have a target value.

Cpm = (USL-LSL)/(6√(sigma2+(Xbar-Target)2)

Cg and Cmk versus Cp and Cpk

Cg and Cmk are calculated the same as Cp and Cpk (respectively). QI Macros uses uses “Cp” and “Cpk” as the default names. And although the calculations are the same, the difference is in the methodology of measurement and how the data is collected.

- Cg examines the equipment-related variation behavior of the measuring system at the location of application. 50 measurements (a minimum of 20) are effected under identical conditions (measurements carried out by the same operator on the same part) or standard and feature at a precisely defined point, and then the deviations of the indications from the nominal indication are recorded.

- Cmk is measured using 50 or more continuous samples produced on a machine, keeping all influences other than the machine parameters constant. Also, the “Cmk” refers to Machine Capability, instead of Process Capability (Cpk).

Min-Max

Min = Min(Xi)

Max = Max(Xi)

Z Score

Z scores help estimate the non-conforming PPM.

Z scores standardize +/-3*stdev values into +/-3.

Zlower = (Xbar-LSL)/stdev

Zupper = (USL-Xbar)/stdev

Zbench

Zbench = normsinv(1-(Expected PPM/1,000,000)) Zbench is the Z score for the Expected PPM

ZTarget/Delta Z

ZT (target) = ΔZ= |Xbar-Target|/(stdev)

Ztarget measures how far the average varies from the Target.

ZT < 0.5 is desired (less than 1/2 standard deviation from target)

The target is assumed to be the midpoint between the USL and LSL.

Sample Size Calculator

Variable

Sample Size (SS) = (ZStdev)/Confidence2

Where:

Z = 1.96 for 95% confidence level

Stdev = standard deviation (or 0.5 Default)

Confidence interval expressed as decimal (e.g., .05 = ±5%)

Attribute

Sample Size (SS) = (Z2p(1-p))/Confidence2

Where:

Z = 1.96 for 95% confidence level

p = percent defects (0-0.5 = 0-50%)

Confidence interval expressed as decimal (e.g., .05 = ±5%)

Correction for Finite Population

new sample size = SS/(1+ (SS-1)/population)

Defects

defects = number of points outside USL-LSL

% Total Defects = (defects100)/(Total points)

Parts Per Million (PPM) and Expected PPM

PPM = % Total Defects*1000000

Expected PPM = (Normsdist(Zlower) + (1-Normsdist(Zupper)))1,000,000

- Expected PPM Short Term (ST), "Within" uses sigma estimator (Rbar/d2 or Sbar/c4)

- Expected PPM Long Term (LT), "Overall" uses standard deviation.

Sigma

If observed PPM > 0, it uses the observed value to calculate Sigma.

If observed PPM = 0, it uses Expected PPM to calculate Sigma.

If both are zero, it defaults to 6 sigma.

If there are no USL/LSL, it leaves it blank.

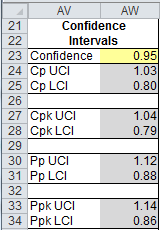

Confidence Interval

The Confidence Interval within QI Macros is set at 95%. However, in the Capability Suite, XbarR and XmR chart templates and dashboards you can set it to your choosing. You will find the settings between the control charts and histogram just below the specification limit settings.

Skewness

A "Skewness" value refers to the degree of asymmetry of a distribution around its mean. Positive skewness indicates a distribution with an asymmetric tail extending toward more positive values. Negative skewness indicates a distribution with an asymmetric tail extending toward more negative values.

Why did My Metrics Turn Red?

- Cp = If Cp > Cpk or Cpk > Ppk. Your process is unstable or data was sorted.

- Cpk = If Cp > Cpk or Cpk > Ppk. Your process is unstable or data was sorted.

- Cr = If Cr is greater than or equal to 1, value turns red. (Cp < 1.0), Cr < 1 then value is not red.

- ZTarget/∆Z = If ∆Z > 0.5, value turns red. Target = (USL-LSL)/2.

- Pp = If Cp > Cpk or Cpk > Ppk. Your process is unstable or data was sorted.

- Ppk = If Cp > Cpk or Cpk > Ppk. Your process is unstable or data was sorted.

Stop Struggling with !

Start creating your in just minutes.

Download a free 30-day trial. Get now!

QI Macros Draws These Charts Too!