Home »

Blog » Pandemic

Improvement Insights Blog

Posts tagged "Pandemic"

My parents and grandparents lived through the early part of the last century – two world wars, Spanish flu, and the Great Depression. My wife’s grandmother caught the Spanish Flu and all of her hair fell out. Maybe we haven’t had the adversity to prepare us for this pandemic, but maybe we can learn from parents and grandparents how to cope.

Riding the Storm Out – REO Speedwagon

“Hi, this is Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“On December 7th, 1941, my 17 year old mother was driving back from Knoxville, Tennessee back to Dayton, Ohio.

Continue Reading "Riding the Storm Out – Lessons from the Last Century"

Posted by Jay Arthur in Improvement Insights.

The pandemic has created a lot of anxiety and panic. There’s a simple way to relieve the stress. Here’s how:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“Some years ago I actually saw a presentation about people having panic attacks, and they had actually MRIed or something the brain to see what’s going on. It turns out that the left hemisphere was all lit up: everything was going on. The left side was going crazy and the right side was dark: there wasn’t much going on at all.

“Well, that’s a panic attack.

Continue Reading "Brain Gym for Pandemic Anxiety"

Posted by Jay Arthur in Improvement Insights.

Vaccine development companies aren’t taking shortcuts; they are using Lean to accelerate delivery of a safe effective vaccine. Here’s how:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“There’s been a lot of anxiety about vaccine development, like, “Oh, they’re short-cutting.” Uh, no. No, okay.

“If you know anything about Lean, you know that the original process was they did phase one trials. Then they evaluated the phase one trial and then they set up a phase two trial. So the phase two trial [is going] and and then they would evaluate all of that and then they would say, “Well, was that okay?”

Continue Reading "Lean Vaccine Development"

Posted by Jay Arthur in Healthcare, Improvement Insights, Lean.

One of the challenges of the pandemic is the ongoing uncertainty. We know to wash our hands, mask our face and stay out of crowds. What can we do to take back some sense of control? Here’s what I’ve been doing.

For some of you, this may seem too “woo-woo” to digest. That’s okay. It’s just an insight from my other studies.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“I don’t know about you, but this whole pandemic thing’s getting a little old, but we know two things for certain: 1 – More people will get sick, and 2 – More people will die.

Continue Reading "Using Your Intuition to Stay Safe During the Pandemic"

Posted by Jay Arthur in Improvement Insights.

The busiest day of the year for long distance calling is Mother’s Day. The recent COVID-19 pandemic revealed the inability of our systems to handle the load. Is your business ready for Mother’s Day?

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“When I worked in the phone company they were very proud of the fact that they had engineered the entire switching system to handle one day out of the year. That one day out of the year was Mother’s Day, because everybody called their mother on Mother’s Day. If we didn’t have ways of switching and routing things and [finding] an empty trunk line… If I was going to call my mom in Tucson from Denver, guess what?

Continue Reading "Are Your Systems Ready for Mother’s Day?"

Posted by Jay Arthur in Improvement Insights.

We know that Lean can collapse cycle time by 75% or more. Here’s what that means for COVID-19:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“If you’ve ever done any Lean projects, you know pretty much if the process is this long {gestures}, with Value Stream Mapping and Spaghetti Diagramming, you can collapse that by maybe 75%, 80%, 90%. You can actually reduce the cycle time for almost anything and do it easily.

“One of the things that is creating optimism for me is that a few years ago I worked with an aerospace manufacturing company, and typically to get a Request For Proposal through, it was 1.9 years for any new part.

Continue Reading "Lean Response to COVID-19"

Posted by Jay Arthur in Healthcare, Improvement Insights, Lean.

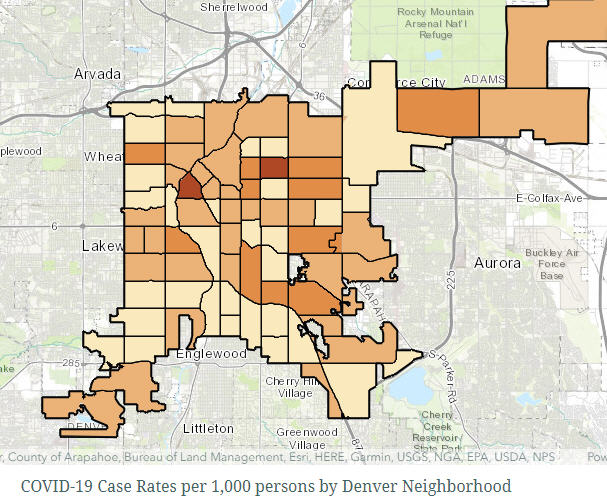

There are COVID-19 hot spots and cold spots. How do we keep the cold spots open and detect and quarantine warming spots? Maybe statistical process control can help.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“Back in the mid 1800s there was a cholera outbreak in London, and John Snow (not of Game of Thrones, but Dr. John Snow) said, “I think there’s a pattern here.” He went out and figured out that everybody who had cholera was getting water from the Broad Street pump. Back then, there was no indoor running water so you had to take your pail, go out to the pump and get your water for your home or your business or your restaurant.

Continue Reading "Cholera and COVID-19 Hot Spot Detection and Quarantine"

Posted by Jay Arthur in Improvement Insights, Six Sigma.

If you’ve ever been sick, you know that the only thing you can do is wait it out. Here’s what we’re going to have to do:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software].

“I know all of you have had some sort of cold or flu or been sick for a while. The day before Thanksgiving in 2014, I had this really heavy cough that came from the darkest recesses of my lungs and I said, “That’s not good.” Then I felt a little worse on Thursday, and on Friday I was diagnosed as having the flu.

Continue Reading "The Economy is Sick"

Posted by Jay Arthur in Healthcare, Improvement Insights, QI Macros.

Coronavirus means that we can’t wait weeks for training and months for improvements. Healthcare has to embrace Agile Lean Six Sigma to handle an infection that could overwhelm existing care facilities. (Hint: This has nothing to do with doctors and nurses, but everything to do with the patient.) Here’s how to do it:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software]. You know, I think we’re at this place in time where we can no longer wait two to four weeks for training and four to six to twelve months for projects to get done.

Continue Reading "Agile Lean Healthcare Now"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.

Nobody wants to look bad, which can make it impossible to make improvements. Here’s why:

“One of the things I’ve learned in all these years working in Quality Improvement is nobody, but nobody, wants to look bad. With the recent coronavirus [outbreak], the doctor who found that and [leaked news] out to the world, the Chinese government tried to shut him down, tried to keep that bit of information inside because they didn’t want to look bad.

“Well, this isn’t just a Chinese or Asian thing – saving face. In any business you walk into, somebody is in charge of how things are working and they’re in charge of trying to make it better, faster, cheaper.

Continue Reading "Nobody Wants to Look Bad"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.