Home »

Blog » Mistake Proofing » Page 2

Improvement Insights Blog

Posts tagged "Mistake Proofing"

The September, 2018 Money magazine article about Bethenny Frankel opens with a rant about Postmates. Frankel ordered a muffin, bagel with cream cheese and a coffee for delivery. The muffin and bagel made it, but without cream cheese or coffee.

Welcome to Hassle America where even simple things seem to be impossible.

We order lunch once a week at the office, but hardly a week goes by without some problem. Last week, Grubhub cancelled our order without telling us. Some weeks the chicken salad comes without chicken. Some weeks we’re missing a dish that was ordered.

Welcome to Hassle America.

Continue Reading "Hassle America – Bethenny Frankel"

Posted by Jay Arthur in QI Macros, Six Sigma.

I recently had to do some home repairs. It’s amazing what you can learn in a 3-minute video and how much time it will save you. The same is true of Lean Six Sigma. Save yourself time and rework. Learn the easy way.

Sign up for my weekly insight videos at: https://www.qimacros.com/free-resources/newsletter/

Continue Reading "Mistake-Proofing With Video Learning"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

My water bill recently doubled. Turns out it’s a design flaw in my Hunter Pro-C controller.

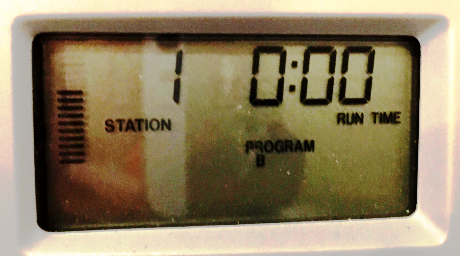

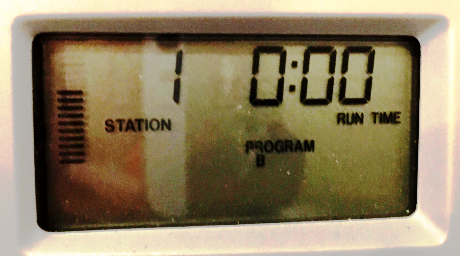

A while back, I set some of my zones to zero minutes.

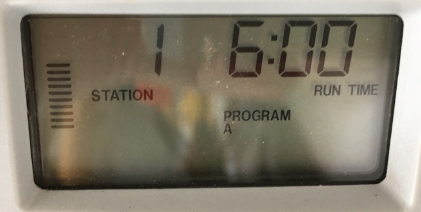

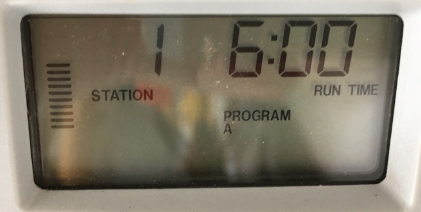

But, if I accidentally hit the minus sign one more time, the controller goes to SIX HOURS:

It was a royal hassle, but I managed to submit an improvement suggestion to Hunter:

There should be no run times below ZERO! Duh!

I had Denver Water come out to show me how to read the meter.

- Meter reader basically said: “Meter’s correct. Fix your controller” and left.

What if they spent 5 minutes helping homeowners check their controller to find the problem?

Continue Reading "Hunter Pro-C Controller Problem"

Posted by Jay Arthur in Jay Arthur Blog, Six Sigma.

I had a breakfast burrito at the Marriott in San Diego last week. I cut it in half and took a bite. I realized there was somthing amiss when I pulled out a strip of plastic. I tried to pull it apart, but it wouldn’t break.

I showed it to the cafe staff and she said: “It looks like an onion.” But a cooked onion would pull apart; the plastic didn’t. I got my money back.

I can imagine that if a machine is cutting onions into strips that it would cut plastic as well. Then the plastic just looks like an onion strip in the egg.

Continue Reading "The Plastic Breakfast Burrito"

Posted by Jay Arthur in Manufacturing, Service, Six Sigma.