Home »

Blog » You searched for trillion » Page 4

Improvement Insights Blog

Latest Posts

ASQ Membership is mainly manufacturing which is only 13% of US employment. How can we start helping the underserved?

Download my “Agile Process Innovation” E-Book

“I’m Jay Arthur, author of “Lean Six Sigma Demystified” and QI Macros [software].

“I was looking at one of ASQ’s media kit things and I was kind of surprised (but not really) when I looked at it and noticed that about 80 percent of the membership is manufacturing but only 13 percent was healthcare or other service-related things.

“The funny thing about that is that’s not how America is employed, right? 80% of America works in service industries and only 13 percent work in manufacturing.

Continue Reading "ASQ Is Missing Out on a Huge Market for Quality"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Manufacturing, Six Sigma.

If you’re a registered NAHQ Next 2020 attendee, you can view Jay Arthur’s showcase until October 31, 2020.

1. Click on the link below.

https://www.webcastregister.live/nahq2020/welcome

2. Click on the NAHQ Next top banner to log in. It will take you to the page below. Log in with your name and email address:

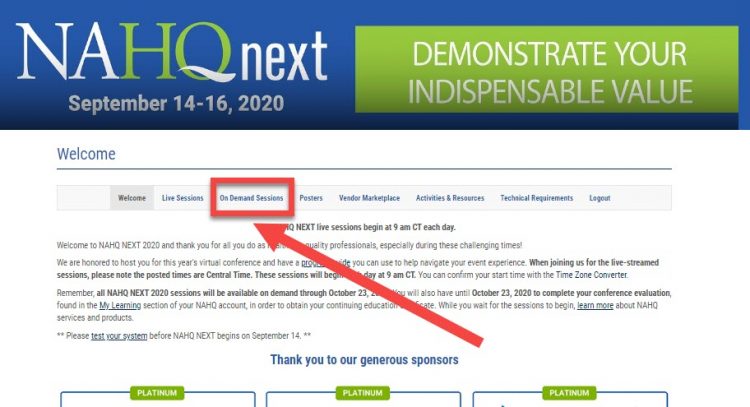

3. Once you’re logged in, visit the On-Demand Sessions and scroll to the very bottom to view Jay’s session, “Zero Harm and the Trillion Dollar Prescription.”

Continue Reading "NAHQ NEXT 2020 HQ Showcase – Jay Arthur"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Jay Arthur Blog, QI Macros.

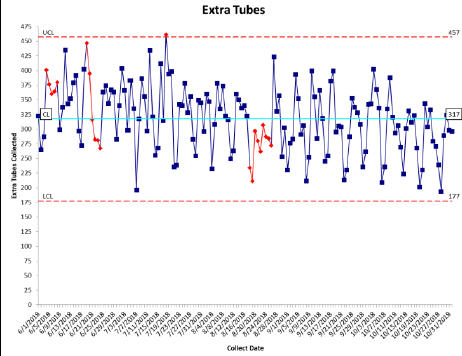

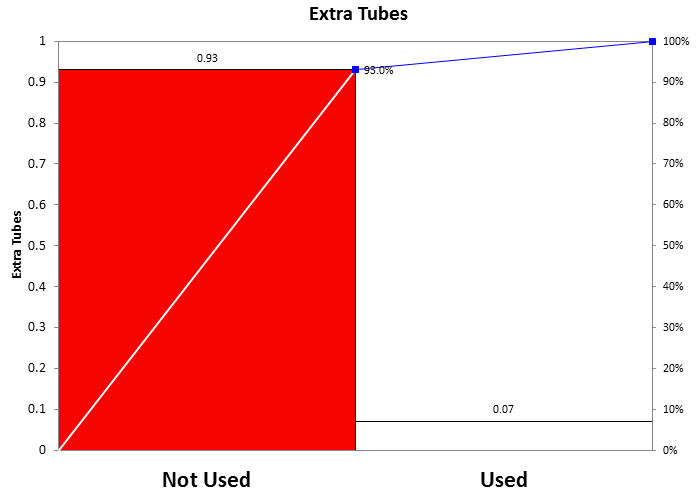

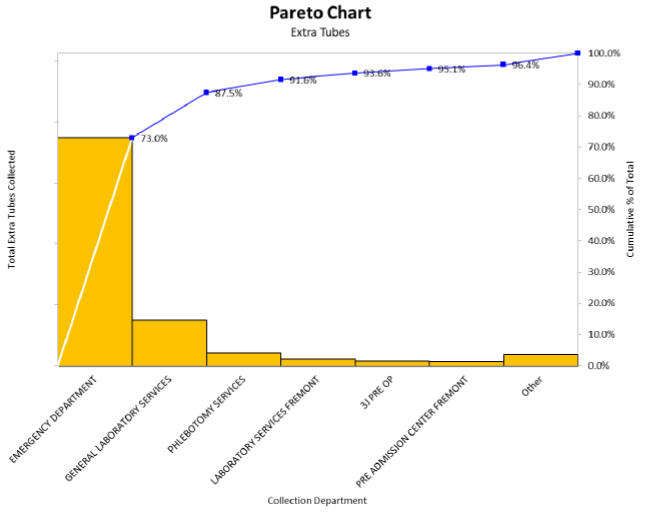

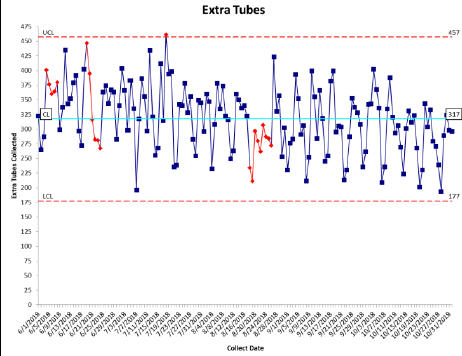

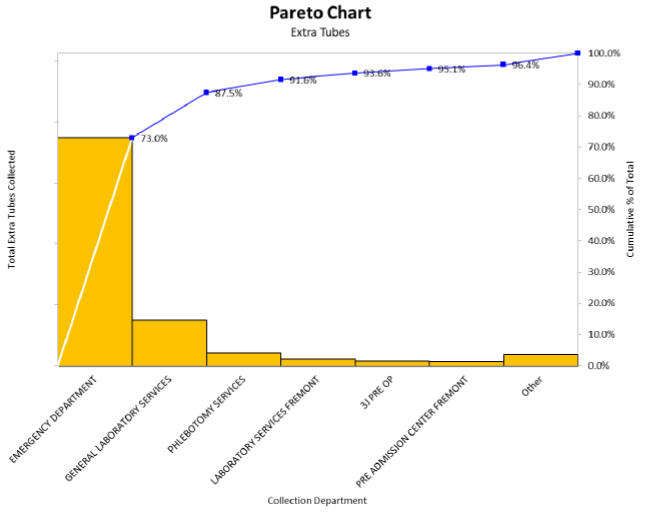

At the ASQ Lean Six Sigma Conference in Phoenix this week, Katie Castree with Accumen presented an excellent improvement story about reducing over-collection of blood tubes in a hospital. Here’s the story:

Baseline: 317 extra tubes of blood collected every day (115,705/year)

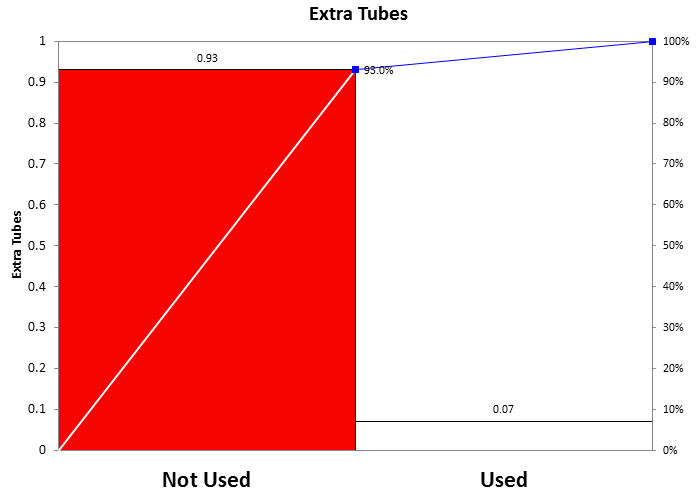

93% of tubes were not used (clinicians thought it was much higher and resisted changing)

Most of the unused tubes were collected in the Emergency Department (focus on the ED, not the entire hospital).

After the countermeasure (not collecting tubes unnecessarily), extra tubes dropped from 317 per day to 118 per day saving $12,335/year and 0.27 FTEs. Over time, extra tubes dropped to only 84 per day, a 74% reduction.

Continue Reading "Reducing Blood Sample Over-Collection"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Jay Arthur Blog, QI Macros, Six Sigma.

Dr. Richard J. Albin, creator of the PSA test for prostate cancer, says that the devastating consequences treatments including surgery and radiation therapy caused:

- 5,000 deaths soon after surgery

- up to 70,000 serious complications

- 50% had persistent blood in their semen

- up to 300,000 suffered impotence, incontinence or both.

He now calls the widespread use of the PSA test a “Public Health Disaster.” As a result of these findings, the U.S. Preventive Services Task Force will recommend that healthy men no longer receive PSA testing.

Unnecessary tests and treatments of all kinds are estimated to cost $250 Billion in the U.S.

Continue Reading "PSA Test – a Public Health Disaster"

Posted by Jay Arthur in Lean, Service, Six Sigma.