Home »

Blog » Six Sigma » Page 9

Improvement Insights Blog

Latest "Six Sigma" Posts

Coronavirus means that we can’t wait weeks for training and months for improvements. Healthcare has to embrace Agile Lean Six Sigma to handle an infection that could overwhelm existing care facilities. (Hint: This has nothing to do with doctors and nurses, but everything to do with the patient.) Here’s how to do it:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software]. You know, I think we’re at this place in time where we can no longer wait two to four weeks for training and four to six to twelve months for projects to get done.

Continue Reading "Agile Lean Healthcare Now"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.

Ordered a snowthrower as a wedding gift for two day delivery. Eight days later it was delivered to someone’s home (not mine). How can we mistake-proof these kinds of problems?

“One of the guys in my office is getting married this June and so I got him an early wedding gift: a snow thrower. So I ordered it from Amazon. I ordered it on Monday, it was supposed to arrive on Wednesday; two days shipping on Prime.

“Then on Wednesday I get this notice that said, “Well, it’s sort of delayed.” So then it said maybe Friday, but of course on Friday it wasn’t here, and they tried to deliver it on Saturday, of course, which is when we’re closed.

Continue Reading "Snowthrower Delivery Debacle"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Service, Six Sigma.

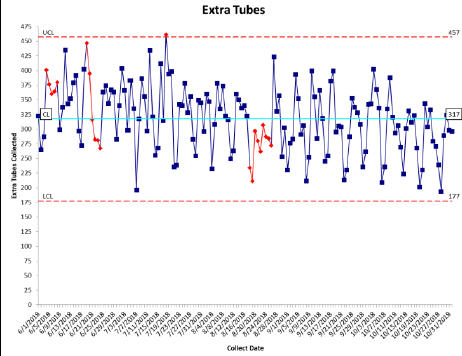

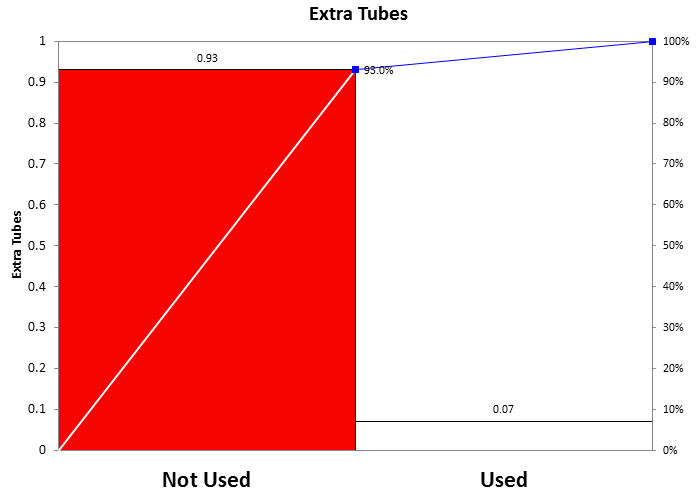

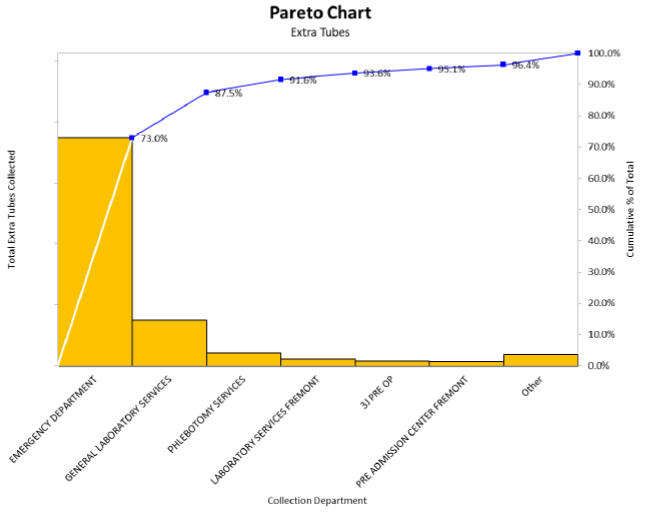

At the ASQ Lean Six Sigma Conference in Phoenix this week, Katie Castree with Accumen presented an excellent improvement story about reducing over-collection of blood tubes in a hospital. Here’s the story:

Baseline: 317 extra tubes of blood collected every day (115,705/year)

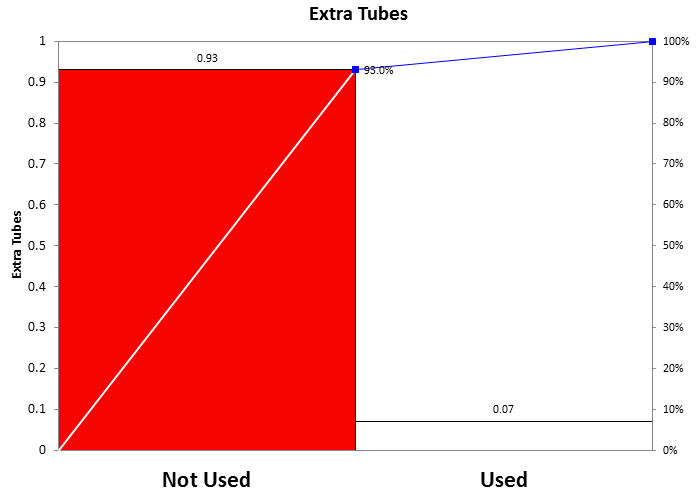

93% of tubes were not used (clinicians thought it was much higher and resisted changing)

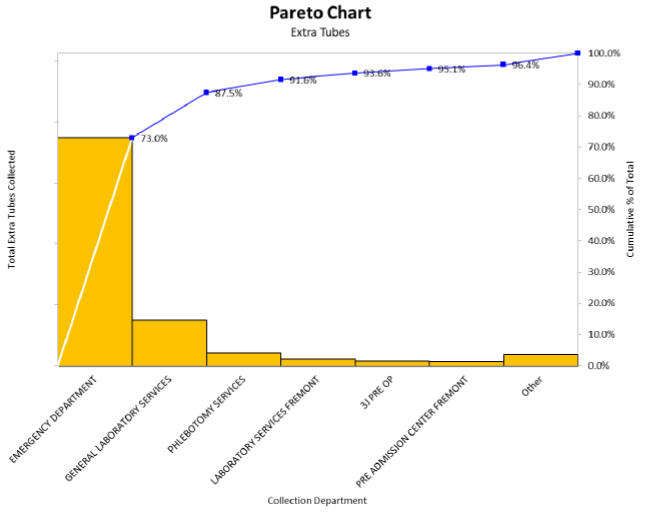

Most of the unused tubes were collected in the Emergency Department (focus on the ED, not the entire hospital).

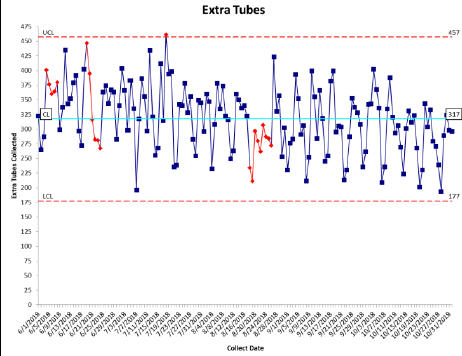

After the countermeasure (not collecting tubes unnecessarily), extra tubes dropped from 317 per day to 118 per day saving $12,335/year and 0.27 FTEs. Over time, extra tubes dropped to only 84 per day, a 74% reduction.

Continue Reading "Reducing Blood Sample Over-Collection"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Jay Arthur Blog, QI Macros, Six Sigma.

Nobody wants to look bad, which can make it impossible to make improvements. Here’s why:

“One of the things I’ve learned in all these years working in Quality Improvement is nobody, but nobody, wants to look bad. With the recent coronavirus [outbreak], the doctor who found that and [leaked news] out to the world, the Chinese government tried to shut him down, tried to keep that bit of information inside because they didn’t want to look bad.

“Well, this isn’t just a Chinese or Asian thing – saving face. In any business you walk into, somebody is in charge of how things are working and they’re in charge of trying to make it better, faster, cheaper.

Continue Reading "Nobody Wants to Look Bad"

Posted by Jay Arthur in Agile Lean Six Sigma, Healthcare, Improvement Insights, Lean, Six Sigma.

Some companies are discovering Agile methods for implementing Lean Six Sigma. Over 50 years of research into how cultures adapt, adopt and reject change can explain why Agile works and why it accelerates Lean Six Sigma adoption.

“I recently did a video about how Christus Health and Novartis and Underwriters Laboratories were all using Agile methods to implement Lean and Six Sigma with one day (sometimes two day) training classes that created Yellow Belts focused on making improvement. I got to thinking about that a little bit, and it turns out that there’s over 50 years of research into how cultures adopt, adapt and reject change.

Continue Reading "Agile Hacks for Making Lean Six Sigma Sticky"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Six Sigma.

My career was dipped in various management methods such as MBO and MBWA. Recently I read a new term: Management by Spreadsheet (MBS). Maybe there’s a better way.

“When I was working at the phone company we had a variety of management fads. I think first there was MBO, or “Management By Objectives.” Of course, that assumed that you know what your objectives were. We had MBWA, “Management By Wandering Around,” so the management team was wandering around all the time and just getting in our way. Recently I saw a different phraseology and I kind of liked it: MBS, which stands for “Management By Spreadsheet.”

Continue Reading "Management By Control Chart"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

Many people take Six Sigma classes but only do one project. “One and Done” as it’s known in the trade. Make a resolution to start making improvements every month! Here are my suggestions.

“Hi, I’m Jay Arthur. It’s 2020, and last week I suggested that you go out and learn one new tool in the QI Macros every month. Now I’m also going to suggest that you set a New Year’s Resolution to make one improvement a month as well.

“Set a goal to do one improvement every month and by the end of the year, you’ll have made 12 improvements and dramatically reduced the amount of waste and rework and lost time and overtime and everything else that is involved in your world, right?

Continue Reading "2020 New Year’s Resolution Part 2 – Improve"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

Many people tell us that they have QI Macros, but they don’t know how to use it. Make a resolution to learn how! Here are my suggestions.

“Hi, I’m Jay Arthur and… it’s 2020. How did that happen? A new year; a new decade. Seems like just yesterday everybody was worried about Y2K. Somebody out there is thinking, “What’s Y2K?” That was a thing that happened back in the year 2000… you probably forgot all about it, but I’ve been at this for over twenty years now in the software field around Quality Improvement, so I’ve seen a lot of things.

Continue Reading "2020 New Years Resolution Part 1 – Learn One Tool Per Month"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

What do Christus Health, Novartis and Underwriters Laboratories have in common? In the last few years they’ve rediscovered the essence of Agile Lean Six Sigma. Here’s How:

“Every year we go out to these conferences and trade shows and exhibit the QI Macros, and I get a chance to go see some of the presentations that people are doing. About two years ago I started to notice an interesting trend, and so I got some observations out of this whole thing.

“So about two years ago, I was at the Lean Six Sigma conference in Phoenix and Christus Health was presenting about their quality journey.

Continue Reading "Agile Process Innovation Case Studies"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, QI Macros, Six Sigma.

The September/October 2019 issue of Harvard Business Review asks this question. The answer is obvious, but some people will read this the wrong way. Here’s why:

“This is a September / October 2019 edition of the Harvard Business Review. You can see here it says, “Are Metrics Undermining Your Business?”

“Now the essence of the article is “Bad metrics drive bad behavior.” Well, I think we all know that, but I think too often people who hate metrics will just look at that and say, “There’s proof! See? Measurements are ruining our business. We’ve got to go back to gut feel, common sense and trial-and-error.”

Continue Reading "Are Metrics Harming Your Business?"

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.