Home »

Blog » Root Cause Analysis

Improvement Insights Blog

Posts tagged "Root Cause Analysis"

There’s one sure sign that you haven’t narrowed your focus using data analysis. You’ll find it in your fishbone diagram.

Download my free ebook Agile Process Innovation.

“Hi, I’m Jay Arthur, author of “Agile Process Innovation,” “Lean Six Sigma Demystified” and QI Macros [software].

“You know, it was kind of interesting to me… we have a Fishbone Diagram in the QI Macros: we have a small, medium and a large. Somebody called in and said, “In this large [diagram] it doesn’t have this the fifth bone for the environment thing…” Nick on my staff went ahead and put one in there for him, but one of the things I know is if you do a good job with data analysis and narrow your focus, you’re going to end up with a minnowbone diagram, not a whalebone diagram.

Continue Reading "Tuna, Minnow and Whalebone Diagramming"

Posted by Jay Arthur in Improvement Insights.

John, a senior executive who went to Japan, told this story of using the “Weapon of Quality” to help out a cabinet making business:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma For Hospitals” and the QI Macros [software].

“I’ve been telling you my story about John, who was a senior executive at a lumber and wood company. It was interesting to me just listening to him talk.

“Once he retired, he was just sitting around and one of his friends who ran a cabinet making business gave him a call and said, “Can you help me out?

Continue Reading "Cabinet Making Quality Story"

Posted by Jay Arthur in Improvement Insights.

Traditional Form-Storm-Norm-Perform models of team development take too long. Here’s how to collapse the time and skip right to perform.

“I was looking at myASQ, and somebody was asking about the four steps of Team development: Form, Storm, Norm, Perform. You know, if you do it traditional (how it usually was taught), it takes a long time for a team to form (come together), storm (fight each other a little bit), normalize their behavior (so they get productive).

“Well, I found that that takes too long. I can’t get to results that way. What I discovered was if I could do the analysis and figure out how to pinpoint where the problem would be, then I can figure out who ought to be on that team to solve that problem.

Continue Reading "Form Storm Norm Perform Takes Too Long!"

Posted by Jay Arthur in Data Mining, Improvement Insights, Jay Arthur Blog.

In school, they always made you search for the one right answer. In real life, things are rarely that simple. There are often many right answers. Here’s how to choose the best among those:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and QI Macros [software].

“I don’t know about you, but in school – first grade all the way through college – it seemed like they were preaching that there was always one right answer to a question. You had to get that one right answer to be able to get a hundred percent on your test (unless it was an essay thing, and then that was a different thing).

Continue Reading "The Myth of the One Right Answer"

Posted by Jay Arthur in Improvement Insights, Jay Arthur Blog, Lean, QI Macros, Six Sigma.

We’re all familiar with Pareto’s rule: 20% of causes produce 80% of the results. But are you familiar with Arthur’s 4-50 rule? Typically, 4% of any process – one step out of 35 – is the cause of more than 50% of waste, rework and lost profit.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and QI Macros [software].

“Now I’ve probably talked to you about this before, but we’re all familiar with Pareto’s rule that 20% of what you do produces 80% of the mistakes, errors, waste, rework, lost profit. 20% of your customers produce 80% of your revenue.

Continue Reading "Arthur’s 4-50 Rule – The Secret to Breakthrough Improvement"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma, Statistics.

That's root cause analysis: What are the common patterns? Where's the Pareto principle?

Continue Reading "Root Cause Analysis in the Time of COVID-19"

Posted by Jay Arthur in Healthcare, Improvement Insights, QI Macros.

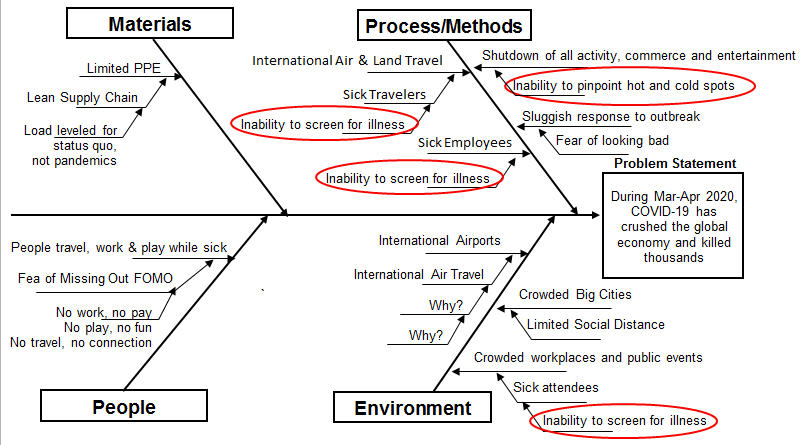

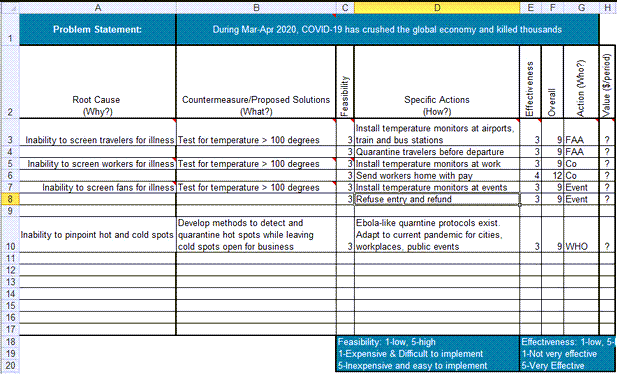

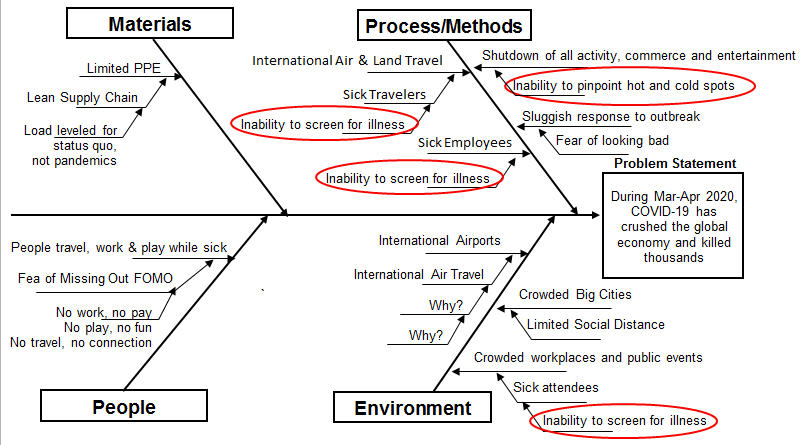

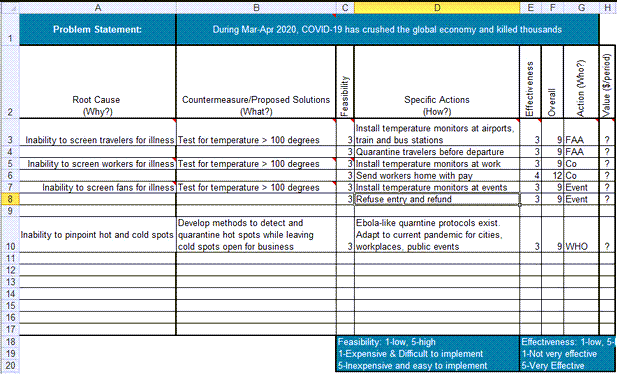

I started wondering, what would the COVID-19 pandemic look like as an improvement story. We have charts about cases and deaths. What might be the root causes and potential countermeasures? Here’s my draft Ishikawa-fishbone root cause analysis diagram and countermeasures. Root causes circled in red.

We screen for guns in luggage and knives on passengers, why not temperatures?

As of 4/12/20, NYC accounted for over a third of U.S. COVID-19 cases and almost 50% of deaths. It’s a hot zone. According to one employee, Denver General Hospital has not had a single COVID-19 patient. It’s a cold zone. What are the boundaries of the cold zone?

Continue Reading "COVID-19 Root Cause Analysis and Countermeasures"

Posted by Jay Arthur in Agile Lean Six Sigma, QI Macros, Six Sigma.

Many people take Six Sigma classes but only do one project. “One and Done” as it’s known in the trade. Make a resolution to start making improvements every month! Here are my suggestions.

“Hi, I’m Jay Arthur. It’s 2020, and last week I suggested that you go out and learn one new tool in the QI Macros every month. Now I’m also going to suggest that you set a New Year’s Resolution to make one improvement a month as well.

“Set a goal to do one improvement every month and by the end of the year, you’ll have made 12 improvements and dramatically reduced the amount of waste and rework and lost time and overtime and everything else that is involved in your world, right?

Continue Reading "2020 New Year’s Resolution Part 2 – Improve"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

Many people tell us that they have QI Macros, but they don’t know how to use it. Make a resolution to learn how! Here are my suggestions.

“Hi, I’m Jay Arthur and… it’s 2020. How did that happen? A new year; a new decade. Seems like just yesterday everybody was worried about Y2K. Somebody out there is thinking, “What’s Y2K?” That was a thing that happened back in the year 2000… you probably forgot all about it, but I’ve been at this for over twenty years now in the software field around Quality Improvement, so I’ve seen a lot of things.

Continue Reading "2020 New Years Resolution Part 1 – Learn One Tool Per Month"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

Does Your Root Cause Analysis Fail The Last Why Because It Presupposes A Solution?

Continue Reading "Solutions Masquerading as Root Causes"

Posted by Jay Arthur in Improvement Insights, Six Sigma.