Improvement Insights Blog

Cpk and Hard vs Specification Limits

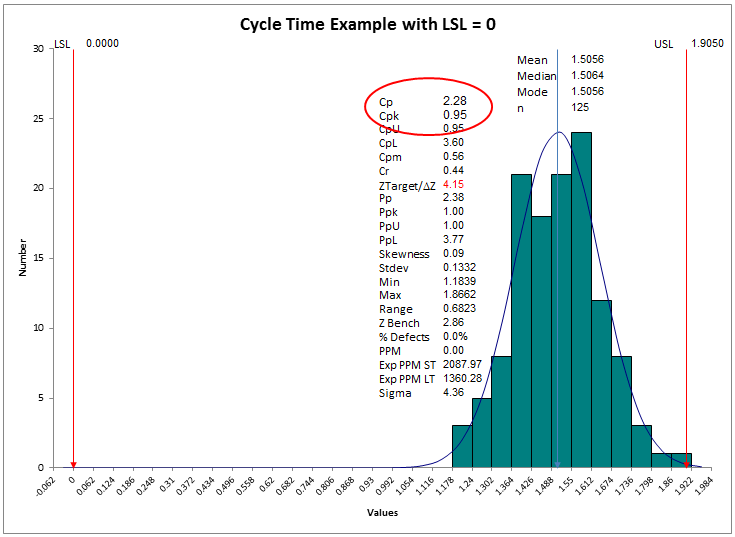

A customer called upset about Cpk. He had a runout of 0.010, but was getting a very low Cpk. Turns out he’d made the classic mistake of confusing a hard limit (e.g., zero) with a specification limit. I had him use QI Macros with an Upper Specification limit (USL) and no Lower Specification Limit (LSL). His Cpk immediately jumped to a more expected value of 1.78.

Later in the day another customer asked why Cpk is calculated as the minimum of the upper or lower Cpk? Because you use the one closest to the average. I think that customer may have had the same problem, confusing a hard limit with a specification limit.

If you have cycle time data, there is no lower specification. Zero is a hard limit, not a specification. If you specify an LSL, you will get a high Cp, but a Cpk less than one.

Cpk when a hard limit confused with a specification limit

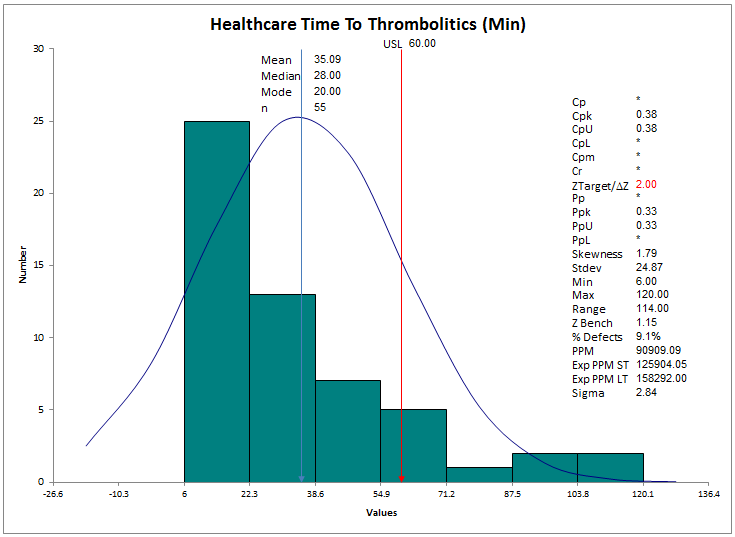

In healthcare, for example, time to thrombolytics should be less than 90 minutes. There is no LSL. Use a USL of 90 to get a proper Cpk.

Histogram with one sided specification limit