Home »

Blog » Capability Analysis

Improvement Insights Blog

Posts tagged "Capability Analysis"

SPC software companies keep trying to gain some edge by tweaking the formulas for various statistics, but is the quest for the next decimal place of precision useful? If you’re trying to send a rocket to Mars? Absolutely. If you’re trying to tune up a business process, not really. Here’s why.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and QI Macros [software]. I’m going to talk to you about what I call The Next Decimal Place.

“Because I’ve been in the software business, [I’ve seen] people and try and change formulas. Let’s say it’s Cp and Cpk.

Continue Reading "The Next Decimal Place"

Posted by Jay Arthur in Improvement Insights, Statistics.

Customer asked me what seemed like a strange question: What specification limits do I need to get a Cp greater than one? Usually her customer should set specification limits, but her boss wanted to know what they could deliver. Hmmmm!

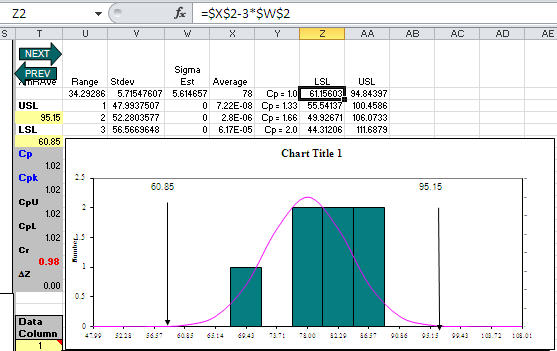

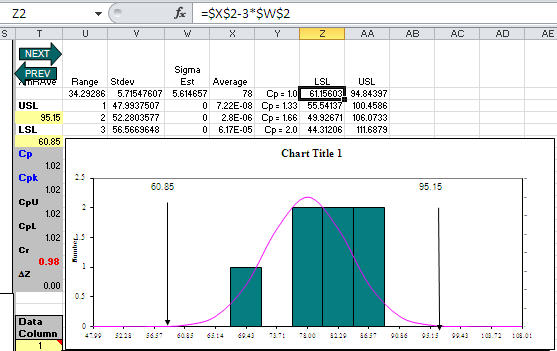

Then I realized that since QI Macros templates (e.g., XmR chart) calculate the average and sigma estimator, the LSL/USL for Cp = 1.0 would be:

LSL = Average – 3*SigEst USL = Average+ 3*SigEst

For Cp = 1.33, just change the 3 to a 4; Cp = 1.66, change the 3 to a 5. Here’s an XmR chart template with some sample data and calculations to reverse engineer spec limits:

Continue Reading "What USL/LSL Do I Need for Cp>1?"

Posted by Jay Arthur in QI Macros, Six Sigma, Statistics.

A customer called upset about Cpk. He had a runout of 0.010, but was getting a very low Cpk. Turns out he’d made the classic mistake of confusing a hard limit (e.g., zero) with a specification limit. I had him use QI Macros with an Upper Specification limit (USL) and no Lower Specification Limit (LSL). His Cpk immediately jumped to a more expected value of 1.78.

Later in the day another customer asked why Cpk is calculated as the minimum of the upper or lower Cpk? Because you use the one closest to the average. I think that customer may have had the same problem, confusing a hard limit with a specification limit.

Continue Reading "Cpk and Hard vs Specification Limits"

Posted by Jay Arthur in QI Macros, Six Sigma.