Home »

Blog » Lean » Page 16

Improvement Insights Blog

Latest "Lean" Posts

Do you know people who only dabble in Lean Six Sigma? They get in, get certified and get out?

You can use the tools of quality everywhere in your life and work for the rest of your life.

Why stop?

Join my Agile Quality Improvement Movement

Continue Reading "Going In and Out of Lean Six Sigma?"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

Are we in the quality community letting our past dictate our future? Is our bias stopping us from seeing the possibilities?

Join the Agile Quality Improvement Movement

Continue Reading "Confirmation Bias In Lean Six Sigma Implementation"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

At ASQ World, Craig Plain gave a fun presentation on Cartoons for Quality.

One of the exercises used a standard work procedure for drawing a pig. Try it yourself

Standard Work Procedure Pig Cartoon Instructions

Here’s mine:

While I’m not normally fond of using games for training, I thought it was interesting how none of us drew exactly the same pig.

Continue Reading "Pig Cartoon – Standard Work"

Posted by Jay Arthur in Lean, Six Sigma.

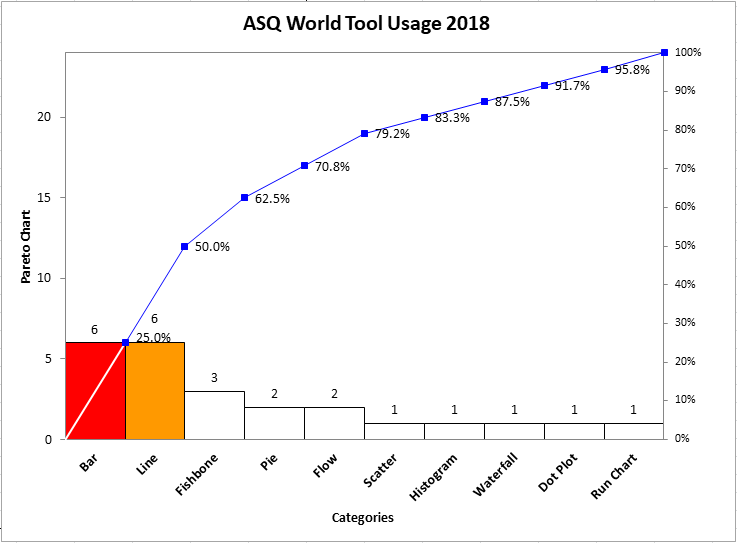

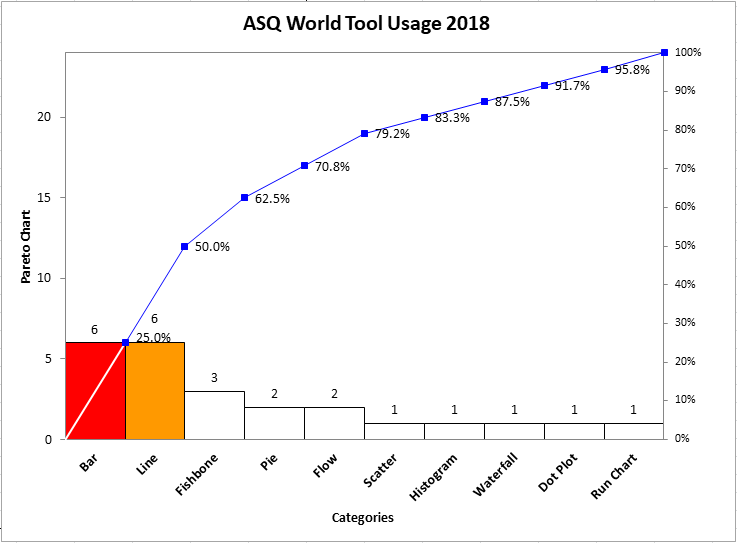

I’m here at ASQ World in Seattle, 2018. As usual, I went through the team presentations to look for quality tool usage. The results are dismal. Mainly line and pie charts.

To paraphrase Steve Jobs, watching people do Six Sigma projects with plain line, bar and pie charts is like watching a man kick a whale across the beach with his bare feet.

Get QI Macros and start using the tools of Quality. Join my Quality Improvement Movement.

Continue Reading "Shortage of Quality Tools at ASQ"

Posted by Jay Arthur in Lean, QI Macros, Six Sigma.

In Win Bigly, Scott Adams describes confirmation bias as the human tendency to irrationally believe new information that supports your existing world view even when it doesn’t. Leaders, managers and team members all think they know the solution to a given problem, even when they don’t. Here’s how confirmation bias can screw up your improvement project.

Join the Agile Lean Six Sigma Movement.

Continue Reading "Confirmation Bias in Lean Six Sigma"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

The editor of Harvard Business Review says that “corporate survival today requires the capacity for rapid change.” Isn’t it time to embrace an Agile approach to Lean Six Sigma to “speed its evolution and better serve customers’ needs?”

Join the Agile Quality Improvement Movement!

Continue Reading "Quality Improvement Movement"

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.

A typical company suffers from 33% waste and rework.

Eliminate the waste and rework with Lean Six Sigma and it will be great for the Earth.

Continue Reading "Earth Day and Lean Six Sigma"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.

The March-April 2018 issue of Harvard Business Review says that “corporate survival today requires the capacity for rapid change.” Even HR is embracing IT’s Agile methodology to “speed its evolution and better serve customers’ needs.”

Isn’t it time to bring Agile to Lean Six Sigma? Read more…

Quality has to accelerate its evolution to keep pace with business and technology.

I’m afraid our old, slow way of implementing Lean Six Sigma is going the way of the dinosaur.

Continue Reading "Agile Lean Six Sigma"

Posted by Jay Arthur in Agile Lean Six Sigma, Lean, Six Sigma.

Does Lean Six Sigma seem like an April Fool’s joke?

Why doesn’t it seem to work sometimes?

Continue Reading "Lean Six Sigma – April Fools!"

Posted by Jay Arthur in Improvement Insights, Lean, QI Macros, Six Sigma.