Home »

Blog » You searched for ASQ » Page 5

Improvement Insights Blog

Latest Posts

The keynote speaker at ASQ World Conference on Quality Improvement reiterated the exponential change challenge. It’s critical to quality professionals everywhere. Here’s what he said:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software].

“I was at the ASQ World Conference in scenic Fort Worth, and oddly enough they had the same keynote speaker they had at the Lean Six Sigma conference in February in Phoenix. Now, I don’t know if ASQ is trying to save money by getting a bulk deal or if they’re trying to send out this message. This guy was talking about how business is changing exponentially, right – not glacially, exponentially.

Continue Reading "Exponential Quality 2.0"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Six Sigma.

Agile Silicon Valley Companies have this motto: Fail Fast, Fail Forward. Here’s how it applies to Lean Six Sigma:

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“I was out at the ASQ World Conference this year and I was observing this guy talking about exponential growth, and he was saying that in Silicon Valley they have a motto: “Fail Fast, Fail Forward.”

“Now I think everybody worries about failing in their first project or whatever it is. No, “fail fast, fail forward,” that’s the Agile approach to things: Rapid iteration to converge on a better world, right?

Continue Reading "Agile – Fail Fast, Fail Forward"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights.

Agile Lean Six Sigma approach will rapidly answer this question. One-day Yellow Belt problem solving will get results where Green Belt and Black Belt training may not.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software].

“I was out at the Lean Six Sigma World Conference in San Antonio there was a very interesting presentation about Yellow Belt trainings. What they found was that if they did it a certain way (which is the way I’ve been doing it for the last twenty years) that they got better results. Well, that’s kind of cool, right?

Continue Reading "Will It Work Here?"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights, Lean, Six Sigma.

One big pharma company embraced a more Agile approach to implementing Lean Six Sigma and achieved quick results. How did they do it?

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“I was at the Lean Six Sigma conference for ASQ in Phoenix and Novartis gave a whole presentation about implementing Lean and Six Sigma around their sales process. It turns out they didn’t actually apply Lean and Six Sigma to the sales process, they simply optimized everything around it that supported their reps going out into the field and how the reps got paid, but they didn’t really do anything about the sales process.

Continue Reading "Minimally Invasive Lean Six Sigma Training"

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.

You’ve heard the phrase “Cart before the horse?” Well one Agile company learned a similar phrase during their implementation. Save yourself a lot of time and effort by learning this simple phrase.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma for Hospitals” and the QI Macros [software]. I was at the ASQ Lean Six Sigma conference and there was a whole presentation on a company that had implemented Agile for software development, and I was kind of stunned to discover that I think they said they spent $15 million implementing Agile. Well, if you’re spending that much money, I’m not sure you’re being Agile, but anyway…

“So the one thing that they really said about implementing Agile for software improvement, the mistake they made was they started doing projects before they improved the process.

Continue Reading "Process Before Projects"

Posted by Jay Arthur in Agile Lean Six Sigma, Improvement Insights.

The job description of the future doesn’t involve manual labor or basic thinking skills. The future will challenge all of us. Here’s why.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software].

“At the ASQ Lean Six Sigma conference there was an opening keynote about the acceleration, the exponential acceleration of technology; how it’s just so much faster, so much quicker, so much… it’s just {whooshing up sound}, right? And the costs are going {whooshing down sound}, and so that’s a dramatic shift from how it used to be.Even Six Sigma used to [have to] make charts manually and do stuff like that, but that’s not how it is any more, so he suggested that you think about it in this map.

Continue Reading "Living Exponentially"

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.

At the 2019 ASQ Lean Six Sigma Conference in Phoenix, a number of Black Belts from major companies told me about the Elephant in the Room that they were afraid to discuss with management even though it was harming their Lean Six Sigma effort. This isn’t the first time I’ve heard this story in companies ranging from manufacturing to healthcare. Watch now to find out what it was.

“Hi, I’m Jay Arthur, author of “Lean Six Sigma Demystified” and the QI Macros [software], and I want to talk to you about the elephant in the room: The thing that I think is actually impeding Six Sigma.

Continue Reading "The Elephant in the Room"

Posted by Jay Arthur in Improvement Insights.

At the ASQ Lean Six Sigma Conference in Phoenix, they said that the world is accelerating exponentially. Is Lean Six Sigma accelerating exponentially? If we use Agile methods to accelerate Lean Six Sigma, we can move Lean Six Sigma into the 21st century.

Continue Reading "Accelerating Lean Six Sigma Exponentially"

Posted by Jay Arthur in Improvement Insights, Lean, Six Sigma.

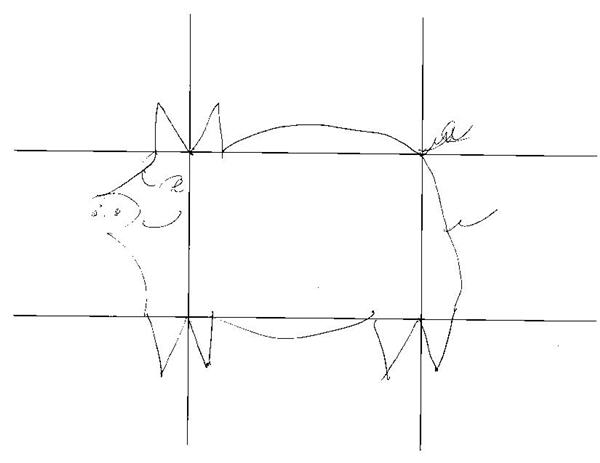

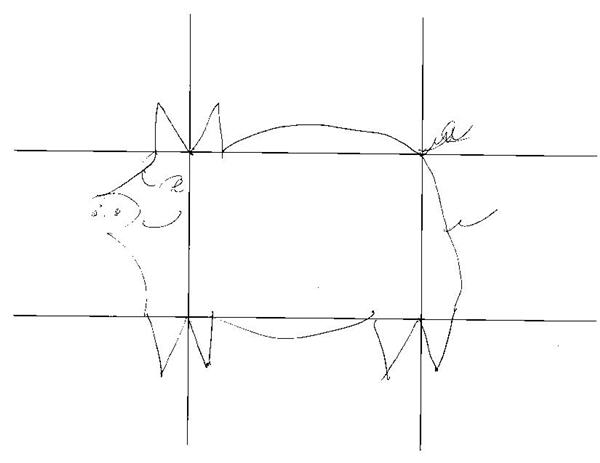

At ASQ World, Craig Plain gave a fun presentation on Cartoons for Quality.

One of the exercises used a standard work procedure for drawing a pig. Try it yourself

Standard Work Procedure Pig Cartoon Instructions

Here’s mine:

While I’m not normally fond of using games for training, I thought it was interesting how none of us drew exactly the same pig.

Continue Reading "Pig Cartoon – Standard Work"

Posted by Jay Arthur in Lean, Six Sigma.

ASQ World 2018, there were a lot of sessions about “Industry 4.0” and the transformation required by quality improvement professionals (Quality 4.0).

Wikipedia describes Industry 4.0 as: “the current trend of automation and data exchange in manufacturing technologies.”

If I can read the writing on the wall, this means that more manufacturing jobs will be automated out of existence, including quality improvement. In the next few years, AI will embody the quality improvement disciplines, and automate detection and autocorrection of performance problems. No human required.

But manufacturing is only 11% of U.S. employment. 80% is service industries. While quality in manufacturing is still important, the rise of service quality improvement is desperately needed in everything from healthcare to fast food.

Continue Reading "Quality 4.0 – Blog entry regarding the current trend of automation and data exchange"

Posted by Jay Arthur in Jay Arthur Blog, Manufacturing, Service, Six Sigma.