Home »

Blog » Six Sigma » Page 25

Improvement Insights Blog

Latest "Six Sigma" Posts

In his speech Sunday at IHI, Don Berwick called for everyone to “recommit to improvement science” (step 5 in ERA 3 of healthcare transformation).

He sounded annoyed with the lack of use of Lean Six Sigma tools and methodologies.

I understand his frustration. I was there in 2006 when he asked everyone to “pledge allegiance to science and evidence.”

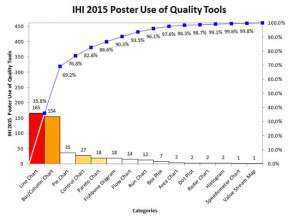

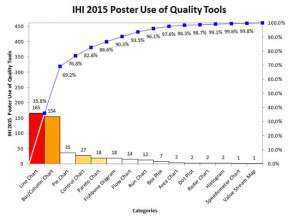

Over the years, I’ve done a stroke tally of the quality tools used in IHI poster presentations.

I gave each poster one checkmark for each type of tool used.

Sadly, even with all of the emphasis on control charts, Pareto charts and other tools of quality, they are used rarely in poster presentations.

Continue Reading "IHI 2015 Poster Use of Quality Tools"

Posted by Jay Arthur in Healthcare, QI Macros, Six Sigma.

The July-August 2015 Harvard Business Review has an article by Particia McDonald, Robert Mecklenburg, MD. and Lindsay Martin on how Intel is driving reduction in health care costs. Intel was projecting that healthcare costs would hit $1 Billion a year in 2012.

Using Virginia Mason’s approach to Lean Healthcare, Intel worked with Cigna and a newly formed Healthcare Marketplace Collaborative (HMC), they were able to reduce the costs of the three most common treatments by 24% to 49%. Evidence based care and eliminating unnecessary tests and care cut more than 10,000 hours from healthcare processes.

Goals: Same-day access to care and rapid return to work.

Continue Reading "Employer-Led Health Care Revolution"

Posted by Jay Arthur in Lean, Service, Six Sigma.

At the ASQ Lean Six Sigma Conference, the QI Macros booth was right next to my biggest competitor–the big dog in the market (you know who they are). A guy comes up to me and says: “We bought 150 copies of their product (pointing to the booth next to me) and it was really expensive. I asked our Green Belts if they were using it and they said No, it’s too hard to use. What are they using; they said Excel.” He went on to say: “I’m thinking about getting the QI Macros because everyone is comfortable with Excel.”

And he wasn’t the only attendee who complained about the same issues: costs too much and too hard to use.

Continue Reading "Complex Statistical Software–a Barrier to Six Sigma"

Posted by Jay Arthur in QI Macros, Six Sigma.

I had a breakfast burrito at the Marriott in San Diego last week. I cut it in half and took a bite. I realized there was somthing amiss when I pulled out a strip of plastic. I tried to pull it apart, but it wouldn’t break.

I showed it to the cafe staff and she said: “It looks like an onion.” But a cooked onion would pull apart; the plastic didn’t. I got my money back.

I can imagine that if a machine is cutting onions into strips that it would cut plastic as well. Then the plastic just looks like an onion strip in the egg.

Continue Reading "The Plastic Breakfast Burrito"

Posted by Jay Arthur in Manufacturing, Service, Six Sigma.

The April, 2014 Harvard Business Review has an article about creating a culture of quality. The authors found that a culture of quality will save $13,400 per employee per year. Surveyed participants also said it takes two hours to fix a mistake. Joseph Juran often said that companies lose a quarter (25%) of their revenue finding and fixing mistakes and errors, so this gives us a benchmark and a reason to embrace quality.

“Companies that take a grassroots, peer-driven approach develop a culture of quality. Traditional strategies have little effect.”

Four Factors that Drive Quality

- Leadership – As Deming said: “The aim of superision should be the help people and machines and gadgets do a better job.

Continue Reading "Creating a Culture of Quality"

Posted by Jay Arthur in Lean, Manufacturing, Service, Six Sigma.

A QI Macros customer recently asked: ” What is a reasonable and productive ratio of Lean or Six Sigma expert (LSSBB, for example) to staff for a healthcare organization that is starting the journey?”

The general consensus I can find online about Six Sigma belts/employees is:

1 BB/100 employees

3 GB/100 employees

I think these numbers are designed to keep Six Sigma training companies in business.

Depending on the size of a Medical center, you could use one BB and some GBs to get started. You can’t fix everything all at once, so one BB ramrodding a handful of GBs to solve key problems would be a good start.

Continue Reading "How Many Green and Black Belts Do You Need?"

Posted by Jay Arthur in Lean, Service, Six Sigma.

This video suggests that 9 out of 10 Americans think that income should be more evenly distributed.

Unfortunately, Vilfredo Pareto found over a century ago that 20% of the people have 80% of the wealth. He felt that even if it was redistributed it would soon fall back to the 80/20 distribution.

Pareto’s Rule is a power law which means that 4% of Americans should hold 64% of the wealth and 1% of Americans should hold 50% of the wealth. According to this video, the top 1% only has 40%. They also pay 40% of the taxes. The bottom 40% of Americans pay no taxes.

Continue Reading "Pareto’s Rule in Wealth Distribution"

Posted by Jay Arthur in Six Sigma.

In this video, Malcomb Gladwell describes the quest for the perfect spaghetti sauce. While one company tried to optimize smooth Italian-style spaghetti sauce, another company discovered that customers wanted chunky sauce and stole the show.

http://www.ted.com/talks/malcolm_gladwell_on_spaghetti_sauce.html

DOE can optimize a product, but may not satisfy your customer’s needs.

In this case, if you asked a customer what they wanted in a spaghetti sauce, they couldn’t tell you (Voice of the Customer). The company tried all kinds of variations in their sauce (spicy, thick, thin, chunky, smooth) and tested them with customers. Spicy and chunky had significant showings. Sometimes you have to listen to the “Stomach of the Customer” (SOC).

Continue Reading "Design of Experiments May Not Satisfy Customers"

Posted by Jay Arthur in Six Sigma.

In a matter of months, an NC dermatology group boosted insurance coding accuracy saving $65,000.

http://www.msochealth.com/lean-six-sigma-dermatology-practice/

While most of the healthcare quality focus is on hospitals, there’s a huge opportunity to make doctor’s offices more effective and efficient. In this case, better coding results in faster payment of insurance claims. Offices can use Lean to reduce patient wait times and increase volume resulting in more revenue and better patient care.

Continue Reading "Dermatology Group Boosts Coding Accuracy from 65.4% to 91.7%"

Posted by Jay Arthur in Lean, Service, Six Sigma.

My wife ordered a set of monogrammed bath robes for our daughter and son-in-law from RedEnvelope. When they arrived, she checked them (unnecessaryinspection)…no monograms.

So she called (rework) and they told her to keep the two unmonogrammed ones (waste) and they would send two monogrammed ones.

A couple of days later, we did get two monogrammed bath robes (rework). The next day we got two more and the day after that we got two more (waste and rework). When we called (rework), they said, don’t return them because they’ve been monogrammed already.

So now, we have eight robes for the price of two.

Continue Reading "Why Retailers Lose Money"

Posted by Jay Arthur in Jay Arthur Blog, Lean, Service, Six Sigma.