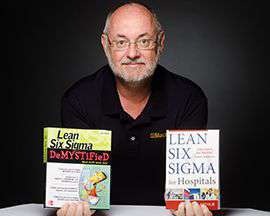

Agile Lean Six Sigma One-Day Workshop with Jay Arthur

Jump-start your team with hands-on training designed to deliver results.

- Avoid high startup costs and months of training. Train up to 25 people, on site, for less than the cost of putting three employees through an online course.

- Start getting results from Lean Six Sigma immediately.

- Learn the seven key tools that will make you look like a Lean Six Sigma expert, even if you’re just starting out.

This training and software is the fastest, easiest, most direct route to bottom-line, profit-enhancing, productivity boosting results from Lean Six Sigma. Learn more about Jay's approach:

Free Perfect and Now, a Lean Six Sigma Moneybelt Manifesto

Lean Six Sigma Myths

Myth #1: Lean Six Sigma training takes 5-20 days; longer training = better training.

- Truth: A five-day training suffers from a core Lean problem: overproduction - too much information. 90% of training is lost after 3 days if it isn't used immediately. By the Monday following a week-long training, you've lost most of it.

- Truth: Too many methods and tools leads to confusion. The "Magnificent Seven" methods and tools will solve 99% of business problems involving delay, defects and deviation.

Myth #2: People learn best from fictional, hypothetical case studies.

- Truth: People learn best from working on their own data and improvement projects. When you've got "skin in the game" you tend to pay attention.

Myth #3: You have to be a statistician to do Six Sigma. You have to know how to calculate all of the formulas and draw all of the charts by hand.

- Truth: You will need Six Sigma software to do Six Sigma, but you don't need to know the math, formulas or statistics. You only need to know how to interpret the charts, graphs and results of analysis.

Myth #4: Six Sigma software is complex and hard to learn.

- Truth: Six Sigma software is complex because it's designed that way. Most Six Sigma software was written using a fill-in-a-form "before mouse" interface. QI Macros was written with a point-and-click, "after mouse" interface that's easy to use.

Myth #5: Lean Six Sigma is hard to learn and apply.

- Truth: Lean Six Sigma is easy. Changing people and culture to adopt or adapt Lean Six Sigma is hard.

If there's one word Jay hears from his clients about his Lean Six Sigma training it's this: PRACTICAL

Is it right for you?

Typical Green Belt Training costs $4,000-$6,000 per person, not including travel. A day with Jay costs just $15,975 including software, travel and materials for up to 25 people.

- Do you have 10 or more employees to train?

- Would you like to save money on tuition and travel?

- Would you like to get training tailored to your needs?

- Would you like to start getting results as quickly as possible?

How can Jay do in a day what others do in five or ten?

Jay is a master practitioner of neuro-linguistic programming (NLP). He understands that people are the biggest roadblock to implementing Lean Six Sigma. Not the methods nor the tools. He doesn't just teach the methods and tools; he teaches the mindset needed for Lean Six Sigma.

You don't need to be a Black Belt in statistical methods to start making big gains. You only need a few key methods and tools and lots of improvements to achieve 5-sigma. By the time you get up to 5-sigma, you'll have pocketed enough money to send anyone you want to Black Belt training. And you'll know who has the aptitude for it.

And we tailor our training to your company's data and needs, because you learn better when it's relevant to your job. Jay gathers data before the class and develops improvement stories for immediate analysis. Jay even likes to develop improvement stories right in the classroom so that you'll be ready to start solving problems and implementing solutions immediately.

Ongoing Support: Jay wants you to succeed, so he provides 90 days of email, phone and webinar support for attendees.

Certification: Participants receive a Yellow Belt Certificate. Participants can refresh their learning at www.lssyb.com.

What People Are Saying...

After we send people to four weeks of Black Belt training, I give them a copy of Jay's Small Business Guerrilla Guide to Six Sigma. I tell them it's a practical way to apply Six Sigma. My copy is dog-eared and highlighted with notes in the margins.

- Master Black Belt, medical device manufacturer

American Society for Quality World conference

With computers available, it is a waste to perform calculations by hand.

Taiichi Ohno

Father of the Toyota Production System

Is Jay Arthur the right instructor for you?

Over the years, Jay has worked with teams that, in a matter of months:

Over the years, Jay has worked with teams that, in a matter of months:

- Saved $20 million in postage expense

- Save $16 million in adjustment costs

- Reduced order errors in a wireless company from 17% to 3% in just four months saving $250,000 a month in rework.

- Reduced denied insurance claims in a healthcare system that saved $330,000 a month with simple process changes that could be implemented immediately.

- Trained a toll road team that saved $1.5 million in expenses their first year and an additional $1 million per year over the following two years.

Jay has found that a handful of methods and tools can solve most quality problems and deliver remarkable results. Using Jay's "just in time" training techniques can jump start your improvements and results.