How to Mistake or Error Proof Your Process

Mistake Proofing for Permanent Improvement

Unfortunately, most processes developed in an ad hoc fashion over time. They are filled with workarounds and unnecessary steps and opportunities for error. Most companies blame people for mistakes, not the system or process. Mistake proofing assumes that instead of training people to fit the "work", you might be better served by improving the "work" to mistake proof the people.

At the 2006 IHI conference, I heard an excellent presentation on error proofing by Blanton Godfrey and other members of the NCSU faculty. It was focused on healthcare, but the ideas presented are universal. And, it offered a structured approach to mistake proofing that incorporates the insights of TRIZ (a methodology for creative problem solving). Here, in a nutshell, is what I learned.

What is Mistake or Error Proofing?

Mistake proofing involves improving work operations including materials, machines and methods to prevent problems due to human error. There are four phases to mistake proofing.

Four Phases of Mistake or Error Proofing

1 Identify Potential Failure Modes (FMEA)

2 Generate Solutions

3 Prioritize and Select Solutions

4 Deploy Solutions

FMEA - Failure Modes and Effects Analysis

- Define the scope of the FMEA. (You can access the FMEA template from the Lean Six Sigma menu of the QI Macros.)

- Assemble the team.

- Graphically describe the process.

- Develop and verify the process flow diagram.

- Identify all subprocesses under each block of this diagram.

- Develop and verify the process flow diagram.

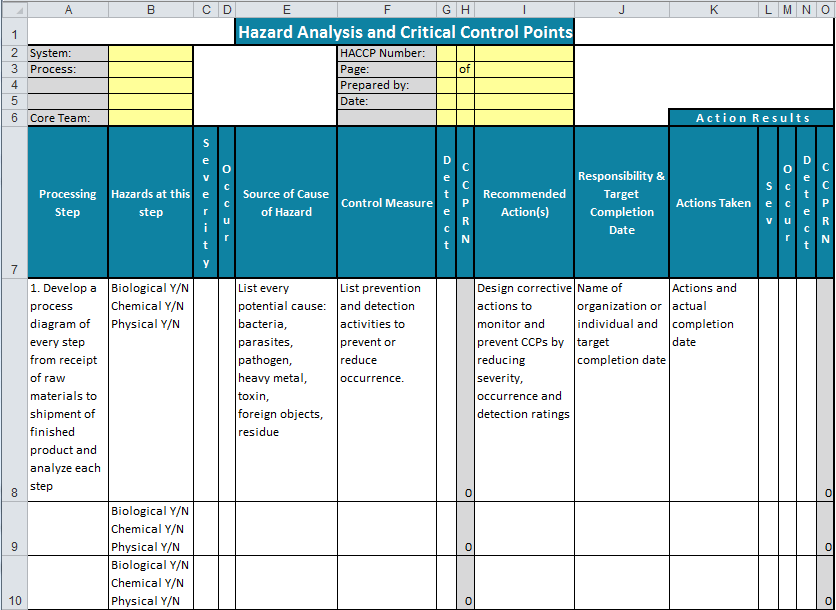

- Conduct a hazard analysis.

- List failure modes for each sub-process. "What can go wrong?"

A failure mode is an action that can potentially create an error in the process. Example: Medication omitted

- Omitted is the action (verb)

- Medication is the object (noun)

- Omitted is the action (verb)

- Determine severity and probability for each failure mode.

- Evaluate the chance of detection for each failure mode.

- List potential causes of the critical failure mode.

- List failure modes for each sub-process. "What can go wrong?"

- Measure actions and outcomes.

General Failure Modes

As you can imagine, there are many common types of failures that can be expected from any business operation:

Process Failure

- Omission:

- What part of the subprocess is prone to be omitted?

- Excessive Repetition:

- What part of the subprocess is prone to be excessively repeated?

- Wrong Sequence:

- In what wrong sequence can the subprocess be executed?

- Early/Late Execution:

- What execution can be early or late?

Selection Failure

- Incorrect Identification/Selection:

- What object of the subprocess is prone to be incorrectly selected or identified?

- Incorrect Counting/Calculating:

- What objects of the subprocess can be counted, measured or calculated incorrectly?

Perception Failure

- Overlooking:

- What information, risk or failure/error is prone to be overlooked?

- Misreading/Misunderstanding:

- What misunderstanding or misreading is prone to occur?

- Incorrect Decision:

- What incorrect decision is prone to occur?

- Miscommunication:

- What miscommunication is prone to occur?

Motion Failures

- Incorrect Transcription/Entering:

- What transcription/entering error is prone to occur?

- Incorrect Route/Orientation/Positioning/Setting:

- What route/orientation/positioning/ setting error is prone to occur?

- Unintentional Touching/Sticking/Splashing:

- What can be unintentionally touched, stuck or splashed?

- Hazardous Movement:

- What movement can cause harm? (walking, slipping, falling)

Other Failures

- Not Available:

- Who/what is prone not to be available?

- Hardware Failure/Incorrect Information:

- What hardware failure or incorrect information provision is prone to occur?

- Unexpected Reaction:

- What unexpected reaction is prone to occur?

There are five mistake proofing principles (elimination, replacement, facilitation, detection, and mitigation) that are useful for developing various solutions. Three of the principles focus on preventing the error; the other two focus on minimizing the effects of a failure:

- Prevent the Error or Mistake Before It Happens

- Elimination - Eliminate tasks or risk

- Replacement - Automate or support

- Facilitation - Simplify, clarify or adjust

- Minimize the Effects of the Error or Mistake After It Happens

- Detection - Record, verify or restrict

- Mitigation - Failsafe, protect or implement redundancy

TRIZ offers various creative solutions for common errors and mistakes. There are many proven ways to apply these five principles :

- Trimming:

- Eliminate a part or process step:

Eliminate manual data entry; eliminate duplicate of questions; eliminate unsafe operations - Self Elimination:

- The mistake eliminates itself:

Feedback of status/performance; broken pills do not roll - Standardization

- Make things the same:

Standard forms; one size fits all; make an asymmetrical part symmetrical - Unique Shapes/Geometry:

- (1 D, 2D, or 3D) - Electrical outlets; symbols

- Copying:

- Redundancy:

Duplicate forms; barcodes; emergency power generator

(e.g., The space shuttle has five computers and two unique sets of software.) - Prior Action

- Pre-package goods, supplies or forms.

- Flexible Films or Thin Membranes:

- Bottle safety seal; package bag; rubber gloves

- Color:

- Color-coded documents, shelves, goods

- Combining

- Customer records; order form with one original and three carbon copies

- Counting:

- Count the number of goods; Use a checklist

- Automation:

- Automatic calculation; electronic verification (bar code; customer record validation)

Questions for Generating Solutions

Here are some questions to help you start generating solutions. They are grouped by principle with the most common solutions listed first:

Principle: Elimination

- Trimming

- Can we eliminate the error-prone process or harmful objects?

- Self Elimination

- Can the harmful action or object eliminate itself?

- Prior Action

- Can we do something beforehand to eliminate the error-prone process or harmful objects?

Principle: Replacement

- Prior Action

- Can we do something beforehand to support human operations?

- Automation

- Can we automate the process to solve our problem?

- Combining

- Can we combine (bring together/closer) two or more things to automate or support human operations?

Principle: Facilitation

- Standardization

- Can we standardize the process to facilitate human operations?

- Combining

- Can we combine (bring together/closer) two or more things tofacilitate human operations?

- Trimming

- Can we trim similar or confusing things to facilitate human operations??

- Copying

- Can we use redundancy to facilitate human operations?

- Prior Action

- Can we do something beforehand to facilitate human operations??

- Flexible Films or Thin Membranes

- Can we use flexible films or thin membranes to facilitate human operations?

- Color

- Can we use color to facilitate human operations?

Principle: Detection

- Self Elimination

- Can people notice abnormalities by themselves?

- Counting

- Can we count something to detect abnormalities??

- Standardization

- Can we standardize the process to detect abnormalities?

- Unique Shape/Geometry

- Can we use shapes (1 D, 2D, or 3D) to detect abnormalities?

- Automation

- Can we automatically inspect something to detect the abnormalities?

Principle: Mitigation

- Copying

- Can we use redundancy to mitigate the effects?

- Trimming

- Can we trim a part of harmful objects to mitigate the effects?

- Prior Action

- Can we do something beforehand to mitigate the effects?

- Standardization

- Can we standardize the process to mitigate the effects?

How to Prioritize Solutions

In the QI Macros, you'll find a countermeasures matrix to assist in prioritizing potential solutions.

Learnings

Every process is subject to similar kinds of human error and mistakes. For each kind of mistake, there are known solutions that can be employed to prevent the problem. All it requires is a fresh look at the process and some creative questions to stimulate mistake proof solutions.

Here's My Point

Isn't it time you to start removing the chance for error from your way of doing business? Or are you content to continue trying to fix your people, not your process?

One-Day Lean Six Sigma Workshop

If you need help getting started, consider scheduling a One-Day Lean Six Sigma Workshop at your company. Download a course outline and pricing information here or give us a call to schedule your session.

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.