Six Sigma and Manufacturing

Six Sigma grew out of Motorola's need to mistake-proof production of cell phones and other electronics. It's based on TQM (Total Quality Management), but with an increased focus on reducing costs to boost profits.

What is Manufacturing?

Those activities relating to the development and production of tangible products. Other terms used to describe these are "plant floor," "production," "a fab," and sometimes "engineering" and "product development." Driven by the marketplace, most manufacturing functions have had to embrace improvement methodologies and SPC just to survive.

I have found that, at an abstract level, there's no real difference between a service process and a manufacturing one. They both encounter delays, defects, deviation and unnecessarycosts. One may produce purchase orders instead of computers, bills instead of brake liners, but they all take time, cost money, create defects, cause rework, and create waste. When we focus on finding the few key measures of defects, delay, and cost that are hampering profits and productivity, breakthrough improvements are easy.

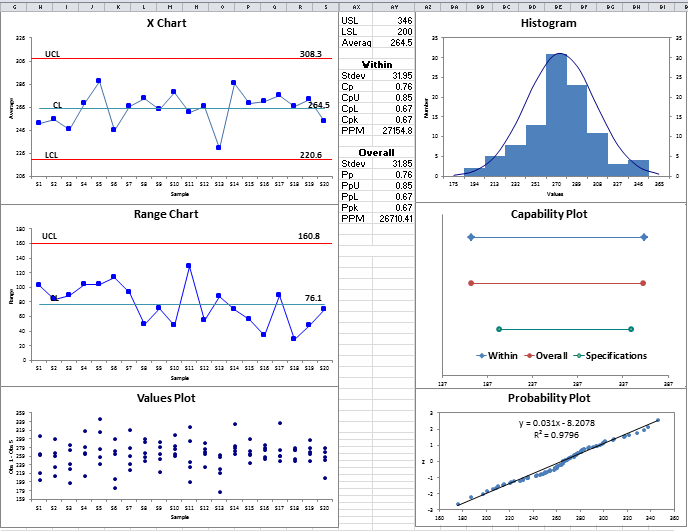

Manufacturing Focuses on Improving Process Capability

I've worked with a number of auto parts suppliers and medical device manufacturers. Every one is focused on improving the process capability metrics: Cp and Cpk. The minimum accepted by most customers is 1.33 (4 sigma) although medical device manufacturers often have higher constraints.

The easiest way to analyze process capability is with the QI Macros Capability Suite. It analyzes both stability (Is the process in control?) and capability (Does it meet customer specifications?)

Every aspect of your business follows a process; it may be a highly refined process or an error-prone, ad hoc one. Regardless of whether it's service or manufacturing, there are always defects in the process steps, delays between steps, and increased costs involved in reworking or scrapping some work product.

Good manufacturing companies often need to improve the backroom service activities: ordering, fulfilling and billing. Use Six Sigma to simplify, streamline and optimize your "service" components.

Key Six Sigma Tools for Manufacturing

Define and Measure

Analyze

Improve

Control

The most commonly used control charts in manufacturing are the XbarR chart and the XmR chart.

Learn More...

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.