Looking for Design of Experiments (DOE) Software for Excel?

QI Macros has ready-made DOE templates for you...

You don't have to be an expert to do DOE!

DOE templates in QI Macros

- Click on QI Macros menu > DOE > Design of Experiments.

- Conduct tests and enter your data in the template.

- QI Macros does the rest.

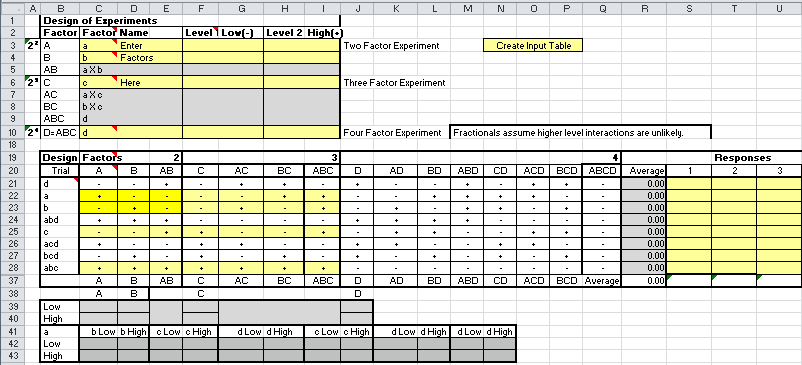

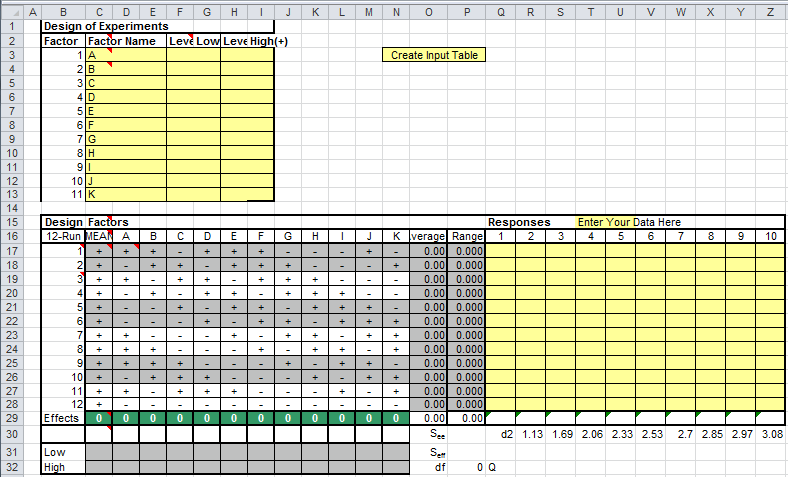

QI Macros Contains These Easy to Use DOE Templates for Excel

- L4 Taguchi

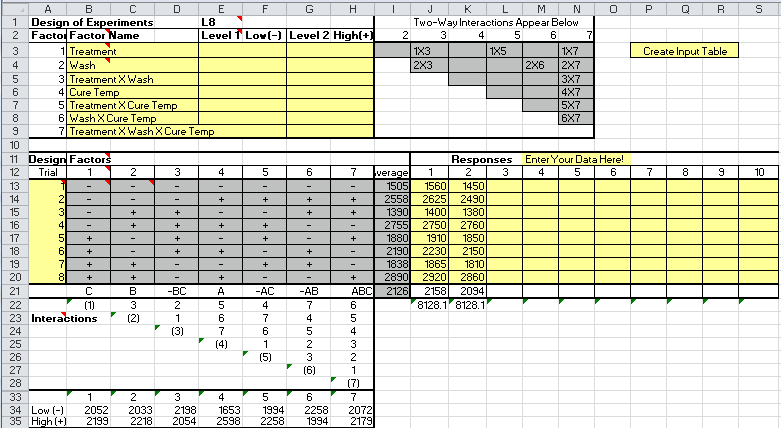

- L8 Taguchi

- L16 Taguchi

- Full Factorial

- Fractional Factorial 8-run

- Fractional Factorial 16-run

- Plackett-Burman 8-run & 8-reflected

- Plackett-Burman 12-run

- Plackett-Burman 16-run

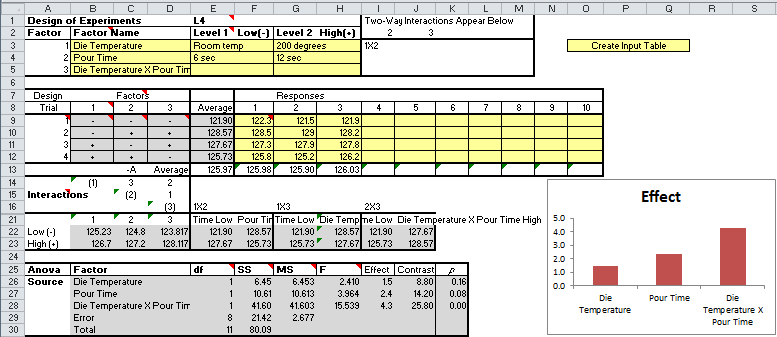

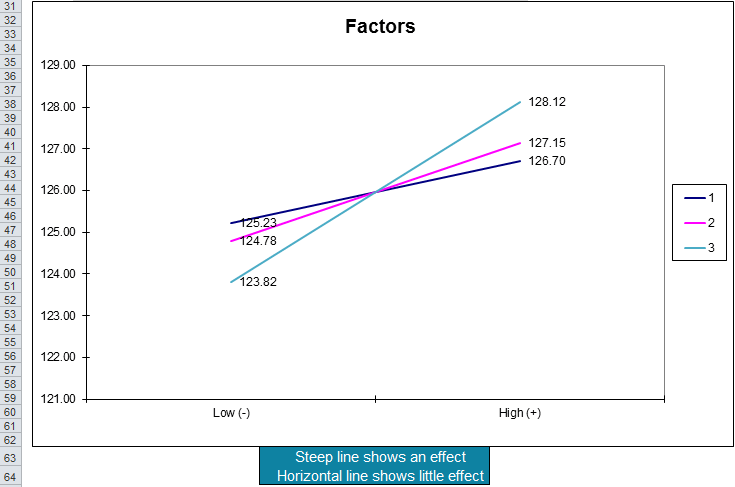

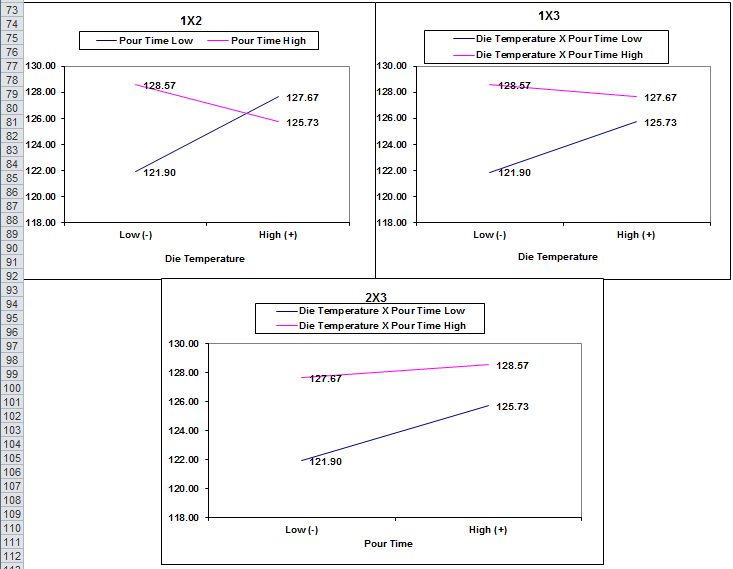

Each template contains an "orthogonal array" of the combinations of high and low values to be used in each trial. Conduct your experiments and then drop your data into the yellow shaded input areas. The templates perform the calculations and draw charts and interactions for analysis. It is recommended to have a minimum of (8) Replications.

Examples of QI Macros DOE Templates for Excel

Learn More ...

- Design of Experiments Overview

- Design of Experiments Example using Popcorn

- Step by step instructions for how to perform a Design of Experiments