Looking for DFSS (Design for Six Sigma) Excel Templates?

QI Macros has Ready-Made DFSS Templates for You.

What is DFSS - Design for Six Sigma?

DFSS is a step-by-step methodology for designing and developing new products or services with at least a 4-Sigma performance.

DFSS and DMADV are Essentially the Same Methodology

- Determine customer needs using Voice of the Customer (VOC)

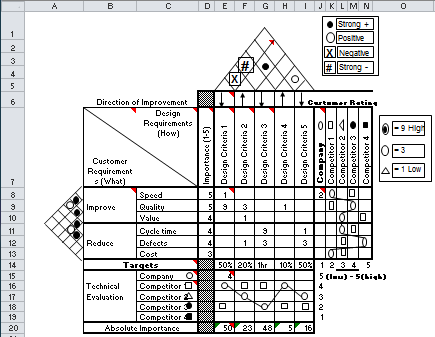

- Translate customer needs into product and process requirements using Quality Function Deployment

- Mistake-proof the process using Failure Modes and Effects Analysis (FMEA)

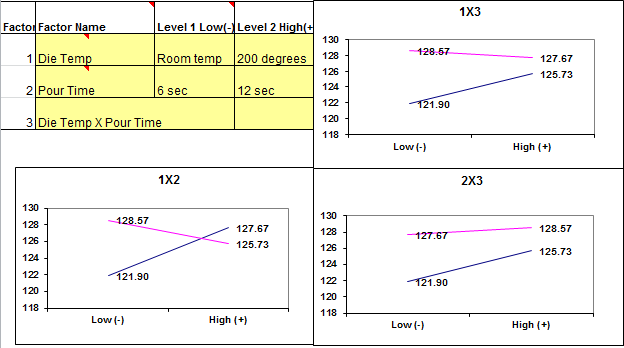

- Design, optimize and test the process using DOE and Critical to Quality Measures (CTQs)

- Develop a Control Plan for monitoring ongoing performance

Most Commonly Used DFSS Tools in QI Macros |

||||

| Define | Measure | Analyze | Design | Verify |

|---|---|---|---|---|

| Project Charter |

Control Chart | QFD | Design of Experiments | Control Chart |

| Voice of the Customer | Histogram | FMEA | TRIZ | |

| Critical to Quality (CTQ) Measures | Pareto Chart | Prioritization Matrix | Action Plan | |

Less Frequently Used DFSS Tools in QI Macros | ||||

| Box and Whisker Plot | Cause/Effect Matrix | Control Plan | ||

| Flowchart |

MultiVari Chart | |||

| Gantt Chart | Scatter Plot | |||

| SIPOC Diagram | Checksheet | Gage R&R (MSA) | ||

| Stakeholder Analysis |

||||

| Tree Diagram | ||||

| Work Breakdown Structure | ||||

Statistical DFSS Tools in QI Macros | ||||

| Descriptive Statistics | Hypothesis Testing |

|||

| ANOVA | ||||

| Chi-Squared | ||||

| t Test | ||||

| Regression Analysis | ||||

| Non-Parametric Tests | ||||

Learn More...

- DMAIC -Define, Measure, Analyze, Improve, Control

- DMADV - Define, Measure, Analyze, Design and Validate

- Gage R&R (MSA) - Analyze measurement systems

Haven't you waited long enough?

Start creating your DFSS Tools in just minutes.

Download a free 30-day trial. Get the DFSS Tools now!

The DFSS Tools is one of many tools included in QI Macros add-in for Excel.

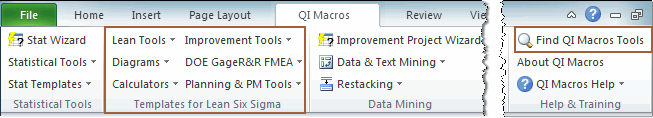

QI Macros adds a new tab to Excel's menu, making it easy to find any tool you need. If you can't locate a tool, use the find tools feature on the far right side of QI Macros menu.

QI Macros Draws All of These Charts!