Implementing Lean Six Sigma

The tools of Lean and Six Sigma work flawlessly, but over 50% of TQM implementations failed and a third or more of Six Sigma implementations fail. The failure is caused by implementation, not the methodology. In the Baby Bell I worked for, we took an "all-or-nothing" approach to implementing TQM: 100s of teams and weeks of training. Months went by and years went by with little to show for it. To make TQM work, we had to go back to basics: laser focus using existing data, improve the mission critical processes, sustain the improvement, and honor our progress.

Most Lean Six Sigma "Black Belt" programs are taking the "all-or-nothing" approach that requires massive investments in training and up to a year before you start seeing any benefit. This "bet the business" approach is hazardous. Instead, you might consider a "crawl-walk-run" approach that will let you maximize your return while minimizing your initial investment. Here's why:

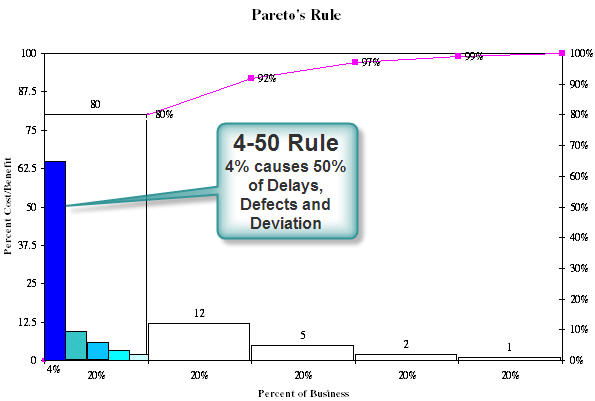

The 4-50 Rule: In case after case working with various businesses, I have found that less than 4% of your business causes over 50% of the waste, rework, cost, and lost profit. That's only only one step out of 25 that causing most of the problems. So forget the old 80/20 rule. Narrow your focus even further to maximize your gains and minimize your Lean Six Sigma startup costs. Only involve 4% of your staff in the initial wave of improvements; in a small business that might be two people looking at data for an afternoon. Start "crawling" with Lean Six Sigma so that you have time to understand and adapt the approach to your business. Then "walk" your way to success on the next 4%, and then the next 4%. Here's why:

Research into how groups of people adopt, adapt or reject changes proves that transformational change begins with less than five percent of the work force. After several "waves" of improvement, these initial explorers will create the "critical mass" necessary for a change like Lean Six Sigma to take root, grow, and spread rapidly across the organizational landscape.

Remember the dark side of the 4-50 rule: 50% of your effort only produces 4% of the benefit. Why bother? Why waste your hard-earned dollars by spreading them over the entire organization, when you can focus and achieve results in just a few key areas. Then, like seeds in the wind, word of mouth will spread the change to a few neighbors, and before long, the employees will convert with minimal resistance and expense.

Start small, focus on mission critical issues, and start driving results.

In my experience, it only takes a matter of a few days to find and solve some of the key problems in any business. It may, however, take a little longer to implement the solutions, but better soon than never. Just use the simple tools of Lean Six Sigma Demystified.

How is Lean Six Sigma Demystified Different?

| Most Lean Six Sigma Programs | Lean Six Sigma Demystified |

| All-or-Nothing | Crawl-Walk-Run |

| Commit to widespread, high-cost, long-term Lean Six Sigma implementation | Laser focus your implementation on the mission critical portions (often less than 4%) of your business that cause over 50% of the delay, defects, waste, rework, and cost. This will minimize your cost while maximizing your benefit. It also maximizes the likelihood of success with Lean Six Sigma. |

| Commit to company-wide training that takes 1-4 weeks and $15,000 per black belt | Use just-in-time training with teams focused on mission critical improvements. Develop people who can find the "mother lode" in your business. Lean Six Sigma should be about results, not training. |

| Randomly pick and train black belts in all of the exotic improvement tools | Establish a track record of success using the fundamental tools of improvement-what I call common science. Then identify the individuals with the people, process, and technical skills to become your black belts. |

| Wait 9-12 months for results | Get immediate results in 3-6 months. |

Don't Make the Same Mistakes

Many companies embarking on the Lean Six Sigma quest are making the same mistakes they made only a decade ago with TQM: measuring progress by people trained, not results achieved. They are trying to train everyone, when it is costly and counterproductive to do so. Here's what I've found:

- 4% of your business produces over 50% of the defects, time, and cost that dampens your productivity and profitability. Why train everyone? Use the data you already have to focus the improvement effort and only train the 4% of your employees who work in these high priority areas.

- Set a BHAG—Big Hairy Audacious Goal—to reduce cycle time, defects, or cost by 50% or more in less than six months.

Most startup companies are at about 2.5 Sigma (17% defects) and most existing companies are at about 3.5 Sigma (3% defects-30,000/million). Using only a line graph, pareto chart, and a fishbone diagram, any company can move up to 5 Sigma (300 defects/million) in 18-24 months. And when you do, you'll stop squandering your profits fixing defects you created along the way. You'll free up people to do meaningful, productive work for your customers. And, best of all, you'll begin to differentiate yourself from all the other companies who produce similar products and services.

Haven't you waited long enough to start achieving these kinds of breakthroughs in speed, quality, and profitability? And you don't have to spend a fortune to do it. You might spend $15,000 or more training one "black belt." When you get to 5 Sigma, you'll need one, but why not start simply with a proven system for process improvement that delivers 50% or greater improvements. It's up to you.

Get Started Now

Start by downloading our "Free Lean Six Sigma Action Plan" that gets you on track to breakthroughs in productivity and profitability using a proven method for systematic improvement that won't cost you a fortune."

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.