The Process Paradox

Peter Keen, in his 1997 book, The Process Edge, uses case studies to describe what he calls the process paradox.

The process paradox: "businesses can decline and even fail at the same time that process reform is dramatically improving efficiency by saving the company time and money and improving product quality and customer service."

I believe we have made a major mistake in our advocacy of continuous improvement. Continuous improvement is the right idea if you are the world leader in everything you do. It is a terrible idea if you are lagging and disastrous if you are far behind. We need rapid, quantum-leap improvement.

- Paul O'Neil chairman of Alcoa.

Wrong Implementation

Most companies are trying wall-to-wall, floor-to-ceiling implementations of Six Sigma. Sadly, this means that 80% of the people are engaged in trying to get less than 20% of the benefit. Wall-to-wall implementations can siphon valuable resources away from satisfying customers, creating new products, and exploring new markets.

Too much training; not enough doing! 90% of what you learn in a Six Sigma class is lost if you don't apply what you've learned within 72 hours.

Wrong Process

Invariably, most Six Sigma teams want to start with a pilot project that's not too risky. Unfortunately, they end up majoring in minor things. They don't get the results required to make a case for Six Sigma.

Wrong Team

Invariably, leaders try to form a Six Sigma team before they've analyzed the data to figure out who ought to be on the team. Consequently, the team struggles because they don't have the right people to solve the problem once it's been stratified to an actionable level.

Here's my point:

Six Sigma can kill your business just as easily as liberate it.

Ruthless prioritization (a.k.a. laser focus): Keen suggests that every business tries to boil the ocean or solve world hunger rather than narrowing their attention to a few customer- and profit-critical, value-adding processes where they can make breakthrough improvements.

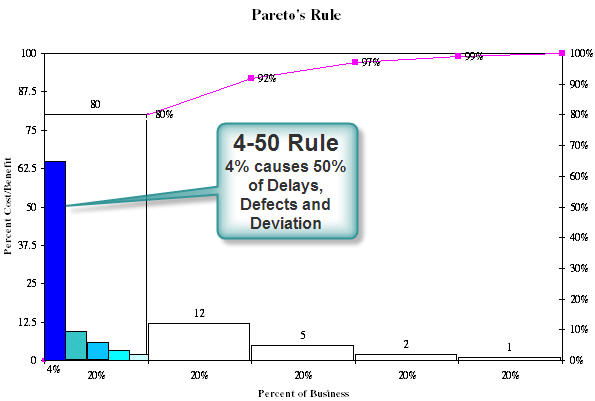

Use the 4-50 rule to narrow your attention to the 4% of your business that causes over half of the lost profit. Tackle the big hairy audacious problems in your business first.

Assets and Liabilities

Keen suggests that every process is either an asset or a liability. It either adds value or it doesn't. He also suggests that there are five types of processes:

- Identity - Processes that define the company to customers, employees and investors.

- Priority - Processes that are critically important to business performance.

- Background - Processes that provide support to other processes.

- Mandated - Required by law (e.g., taxes).

- Folklore - Legacy processes that have no value.

Process |

Asset |

Liability |

Identity |

||

| Priority | ||

| Background | Repair and rework | |

| Mandated | ||

| Folklore |

Far too many departments and individuals think that fixing mistakes is an asset to the business. It's a liability because it eats profit and reduces growth.

- Isn't it time to narrow your focus to some mission-critical, priority processes?

- Use data to narrow your focus to the 4-50.

- Stop training everyone. Train 4-50 team members just-in-time, right before they embark on the problem solving process.

- Aim for breakthrough (50% reduction in defects or delay).

- Stop majoring in minor things.

Keep your business healthy!

Rights to reprint this article in company periodicals is freely given with the inclusion of the following tag line: "© 2008 Jay Arthur, the KnowWare® Man, (888) 468-1537, support@qimacros.com."

Take our FREE Lean Six Sigma Yellow Belt training online.

Take our FREE Lean Six Sigma Yellow Belt training online.